-

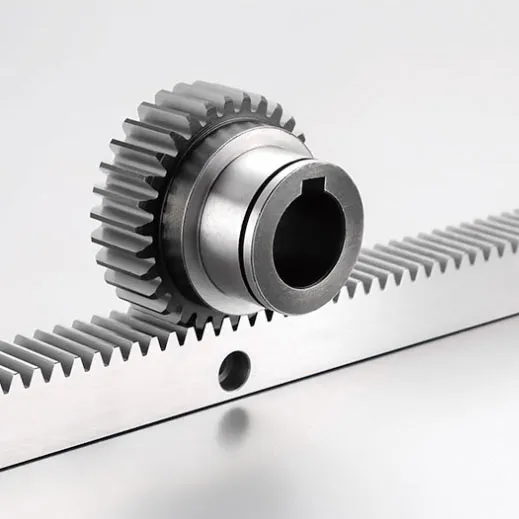

Gear Rack Classification

Rack straight and helical teeth

The rack module is divided into: M1.25 M1.5 M2.5 M3

Large load type M4 M5 M6 M8 M11

Accuracy Grade

Q5 (DIN5)

Q6(DIN6)

Q7(DIN7)

Q8(DIN8)

Q9(DIN9)

Q10(DIN10)

-

Gear Rack Features

Fixed and accurate transmission ratio:

Gear rack transmission can ensure a constant transmission ratio, making power transmission stable and reliable, especially suitable for situations where precise control of output speed and torque is required.

Smooth transmission:

The gear rack meshes with involute gears, resulting in low contact stress, low friction coefficient on the tooth surface, smooth operation, and minimal vibration and noise.

Compact structure:

Gear rack transmission can achieve a larger transmission ratio in a smaller space, making the entire transmission system smaller in size.

Capable of transmitting large power:

Gear and rack transmission can transmit large power, with a circumferential speed of up to 300m/s, a transmission power of up to 105KW, and a wide range of gear diameters.

Long distance docking can be achieved:

Extending the rack can connect with reserved adjustment gaps, allowing for unlimited length docking, ensuring the continuity and stability of the transmission.

-

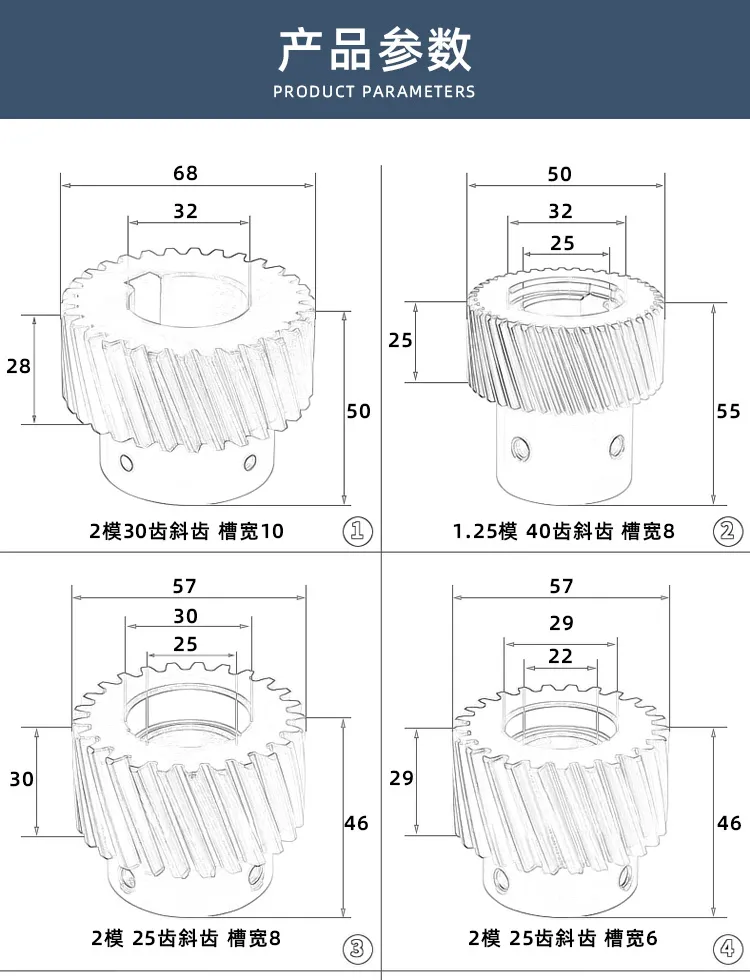

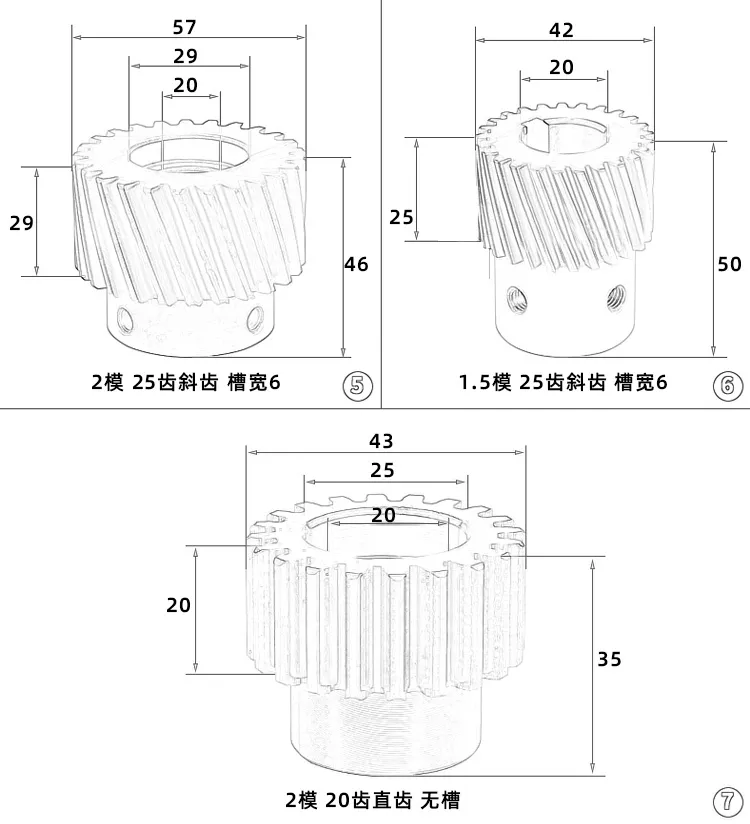

Gear Rack Parameters

The main parameters of gears and racks include modulus and number of teeth:

Modulus: represents the size of the gear and rack. The larger the modulus, the stronger the load-bearing capacity of the gear and rack, but the manufacturing difficulty will also increase accordingly. The selection of modulus should be determined based on actual usage requirements and manufacturing process level.

Number of teeth: determines the gear ratio and transmission accuracy. The more teeth there are, the more stable the transmission ratio and the higher the transmission accuracy, but it also increases the manufacturing difficulty and cost.

-

Gear Rack Industry Application

-

Laser cutting machine and laser engraving machine

-

Precision CNC+truss manipulator

-

Heavy duty truss manipulator/ground rail robot

-

Large CNC lathe/casting machining center

-

-

Gear Rack Performance Advantages

1、Extreme load capacity, a single system can bear up to 15-20 tons of axial load, and the stress is dispersed through multi-point meshing design.

2、Infinite extension feature, supports modular splicing, and the travel can be extended to hundreds of meters.

3、No need for high-precision pre tightening adjustment, reducing installation complexity.

4、After wear, the accuracy can be restored by adjusting the meshing clearance (such as reverse gear gauge calibration).

5、Anti deformation ability, wide rack structure (common width ≥ 50mm) has excellent anti bending performance, avoiding deformation problems caused by self weight under long stroke.

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.