-

Product Features

Square spline nut direct installation structure

Adopting a rigid square spline female design, without the need for additional support seats, it can be directly integrated into the equipment body, greatly saving space and improving system rigidity.

High torque bearing mechanism

Six rows of ball bearings are evenly distributed around the spline shaft at 120 ° intervals, and the ineffective travel at the corners is eliminated through preloading technology, achieving zero clearance transmission and significantly improving torque resistance.

Multi functional shaft body optional

Provide options for solid and hollow shafts, with solid shafts suitable for conventional loads; Hollow shafts support internal wiring, piping, or exhaust, expanding application scenarios.

High load capacity

The dense arrangement design of ball bearings can withstand large radial and axial forces, adapting to impact or vibration environments.

Long lifespan and low maintenance requirements

Rolling contact reduces material loss, and most models are equipped with sealing rings or protective covers to reduce dust and debris intrusion and lower maintenance frequency.

Compact structure and lightweight

Integrate rotation and linear motion functions to reduce the space occupied by additional guide rails or bearings.

-

Product Application

Precision machinery: semiconductor wafer handling equipment, high-precision testing instruments,

Automated production line: robotic arm rotating joint, material rotating table,

Special environmental equipment: medical equipment transmission system, clean room machinery,

-

Product Detail

-

-

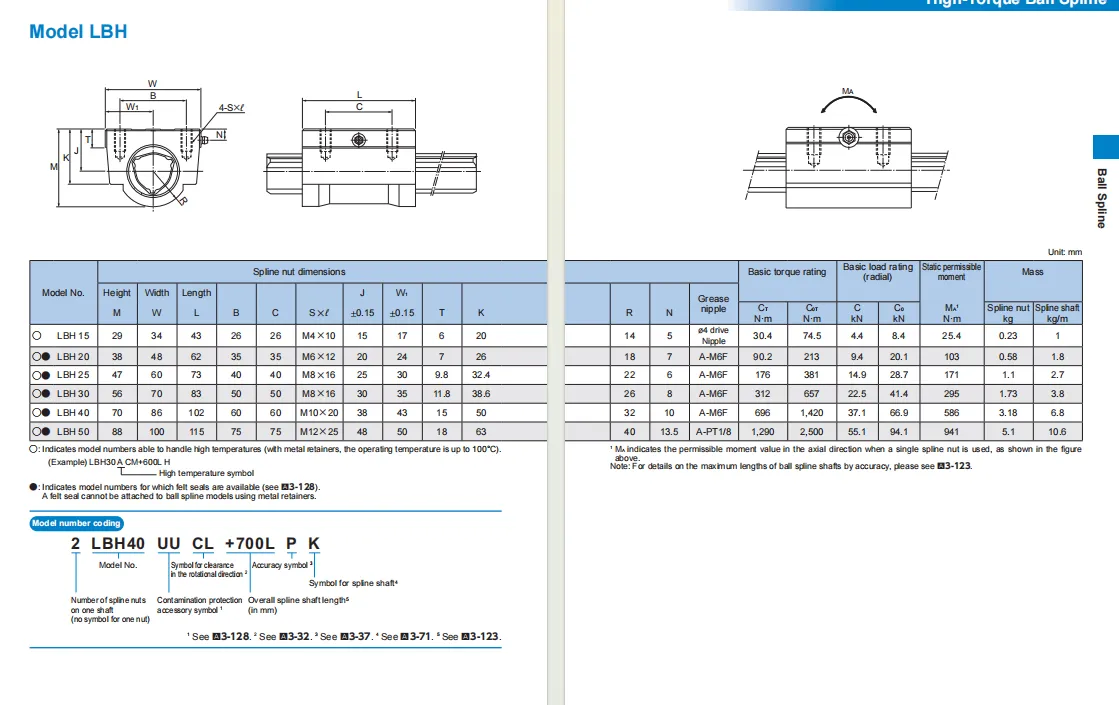

Product Parameters

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.