-

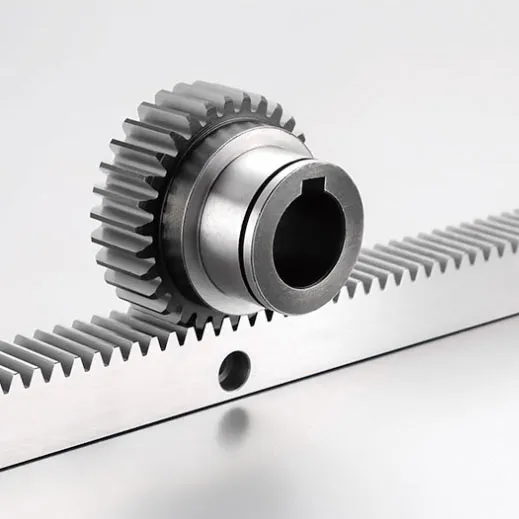

Gear Rack Classification

To'g'ri va spiral tishlarni mahkamlang

Raf moduli quyidagilarga bo'linadi: M1.25 M1.5 M2.5 M3

Katta yuk turi M4 M5 M6 M8 M11

Aniqlik darajasi

Q5 (DIN5)

Q6(DIN6)

Q7(DIN7)

Q8(DIN8)

Q9(DIN9)

Q10 (DIN10)

-

Gear Rack Features

Ruxsat etilgan va aniq uzatish nisbati:

Tishli tokchali uzatmalar doimiy uzatish nisbatini ta'minlab, elektr uzatishni barqaror va ishonchli qiladi, ayniqsa chiqish tezligi va momentni aniq nazorat qilish zarur bo'lgan holatlar uchun mos keladi.

Silliq uzatish:

Tishli tokcha involyut tishli uzatmalar bilan to‘rlanadi, buning natijasida past kontaktli kuchlanish, tish yuzasida ishqalanish koeffitsienti past, silliq ishlash va minimal tebranish va shovqin paydo bo‘ladi.

Yilni tuzilish:

Tishli tokchali transmissiya kichikroq maydonda kattaroq uzatish nisbatiga erishishi mumkin, bu esa butun uzatish tizimini kichikroq qiladi.

Katta quvvatni uzatishga qodir:

Tishli va tokchali uzatmalar katta quvvatni uzatishi mumkin, aylana tezligi 300 m/s gacha, uzatish quvvati 105 KVtgacha va tishli diametrlarning keng diapazoni.

Uzoq masofaga o'rnatishga erishish mumkin:

Rafni uzaytirish zahiradagi sozlash bo'shliqlari bilan ulanishi mumkin, bu esa cheksiz uzunlikdagi o'rnatish imkonini beradi, uzatishning uzluksizligi va barqarorligini ta'minlaydi.

-

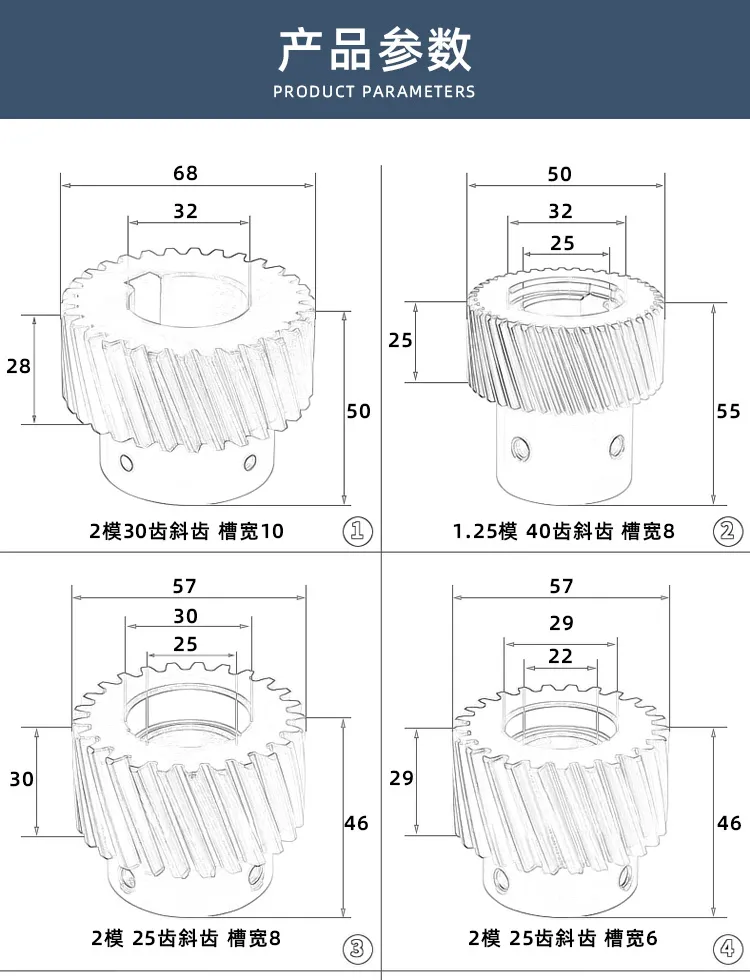

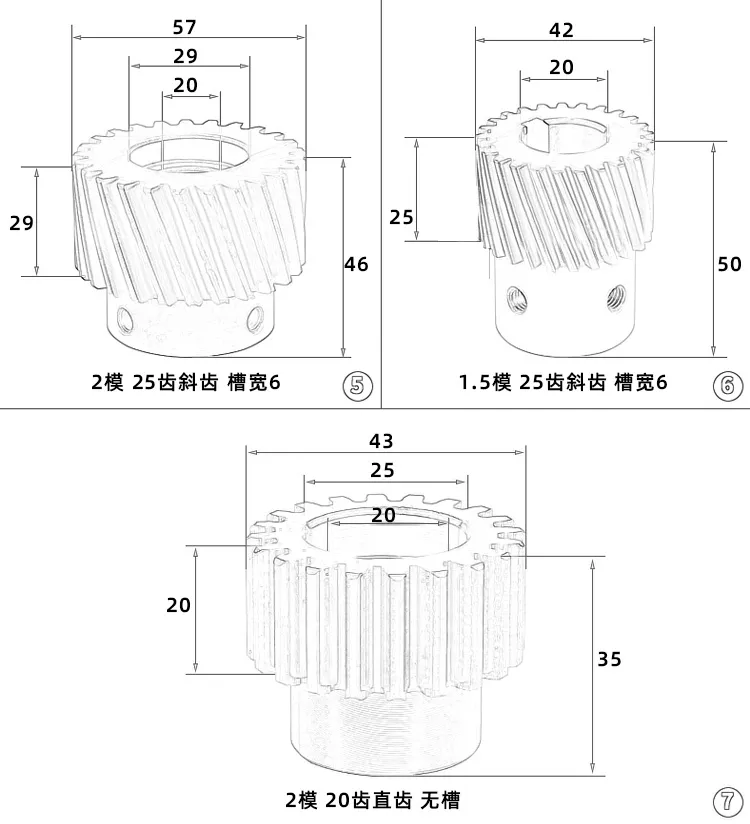

Gear Rack Parameters

Tishli va tokchalarning asosiy parametrlariga modul va tishlar soni kiradi:

Modul: tishli va rafning o'lchamini ifodalaydi. Modul qanchalik katta bo'lsa, tishli va rafning yuk ko'tarish qobiliyati shunchalik kuchli bo'ladi, ammo ishlab chiqarish qiyinligi ham shunga mos ravishda ortadi. Modulni tanlash haqiqiy foydalanish talablariga va ishlab chiqarish jarayoni darajasiga qarab belgilanishi kerak.

Tishlar soni: vites nisbati va uzatish aniqligini aniqlaydi. Tishlar qanchalik ko'p bo'lsa, uzatish nisbati qanchalik barqaror bo'lsa va uzatish aniqligi shunchalik yuqori bo'ladi, lekin bu ishlab chiqarish qiyinligi va narxini oshiradi.

-

Gear Rack Industry Application

-

Lazerli kesish mashinasi va lazerli o'yma mashinasi

-

Nozik CNC + truss manipulyatori

-

Og'ir truss manipulyatori / yerdan relsli robot

-

Katta CNC torna / quyma ishlov berish markazi

-

-

Gear Rack Performance Advantages

1, Haddan tashqari yuk ko'tarish qobiliyati, bitta tizim 15-20 tonnagacha eksenel yukni ko'tarishi mumkin va stress ko'p nuqtali to'r dizayni orqali tarqaladi.

2, Cheksiz kengaytma xususiyati, modulli ulanishni qo'llab-quvvatlaydi va sayohatni yuzlab metrgacha uzaytirish mumkin.

3, O'rnatish murakkabligini kamaytiradigan yuqori aniqlikdagi oldindan mahkamlashni sozlashning hojati yo'q.

4, Eskirgandan so'ng, to'r bo'shlig'ini sozlash orqali aniqlikni tiklash mumkin (masalan, teskari vites o'lchagichni kalibrlash).

5, Deformatsiyaga qarshi qobiliyat, keng raf tuzilishi (umumiy eni ≥ 50 mm) mukammal egilishga qarshi ko'rsatkichga ega, uzoq zarba ostida o'z vaznidan kelib chiqadigan deformatsiya muammolaridan qochadi.

-

O'rtacha etkazib berish muddati qancha?

Narx so'rash

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.