-

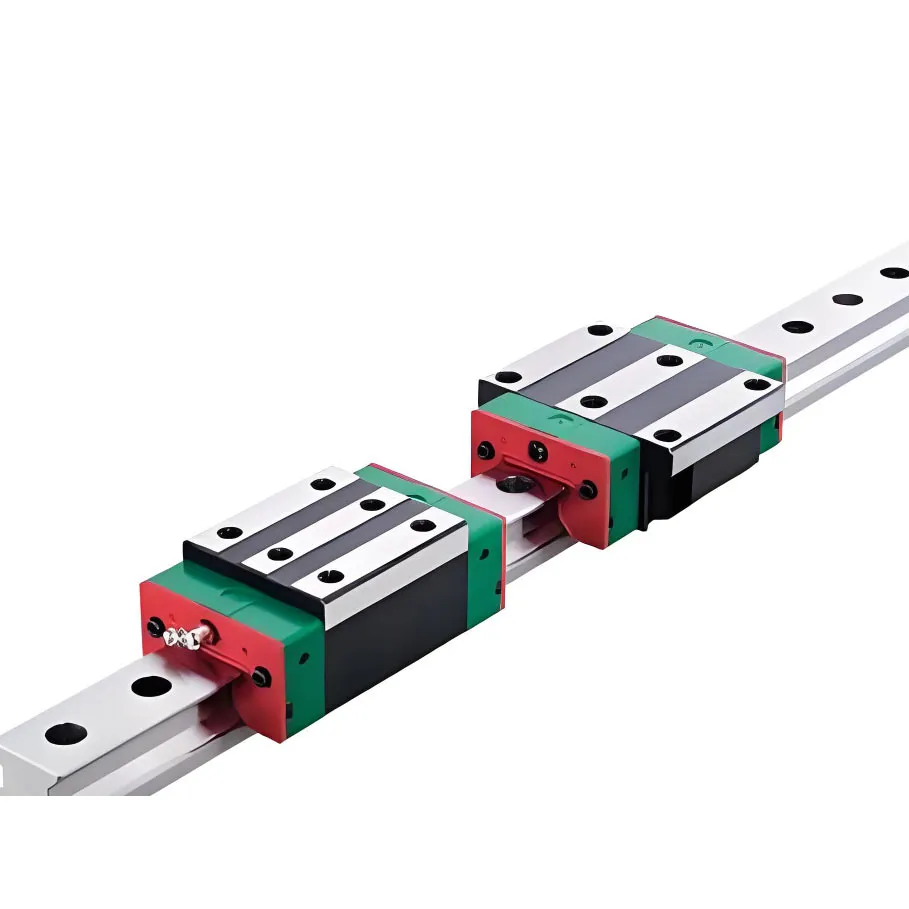

Guide Linear Classification

1、Classify by rolling element type

Type

Characteristic

Ball type linear guide

Low frictional resistance and high motion accuracy

Roller type linear guide

High rigidity, high load

2、Classified by structural shape

Type

Characteristic

Rectangular guide rail

The structure is simple, easy to process, and has a large load-bearing width,

Arc guide rail

High load-bearing capacity, high stability, flexible installation, easy maintenance and upkeep

Cylindrical guide rail

Simple manufacturing, high precision requirements

3、Classified by performance indicators

Type

Characteristic

High precision linear guide

Select grinding grade processing technology

Heavy load linear guide

Using Cr/Mo alloy steel material

High speed silent linear guide

Low friction, silent

Micro linear guide

Extremely compact design

Product Grade

Grade Name

Walking parallelism (100mm guide rail)

Applicable scenarios

Common(C)

≤5μm

Simple automation equipment, ordinary packaging machinery

senior(H)

≤3μm

Precision machine tool non critical axis, conventional printing equipment

Precision grade(P)

≤2μm

Key axes of CNC machine tools and high-precision measuring instruments

Ultra precision grade(UP)

≤1.5μm

Semiconductor wafer manufacturing, optical focusing equipment

-

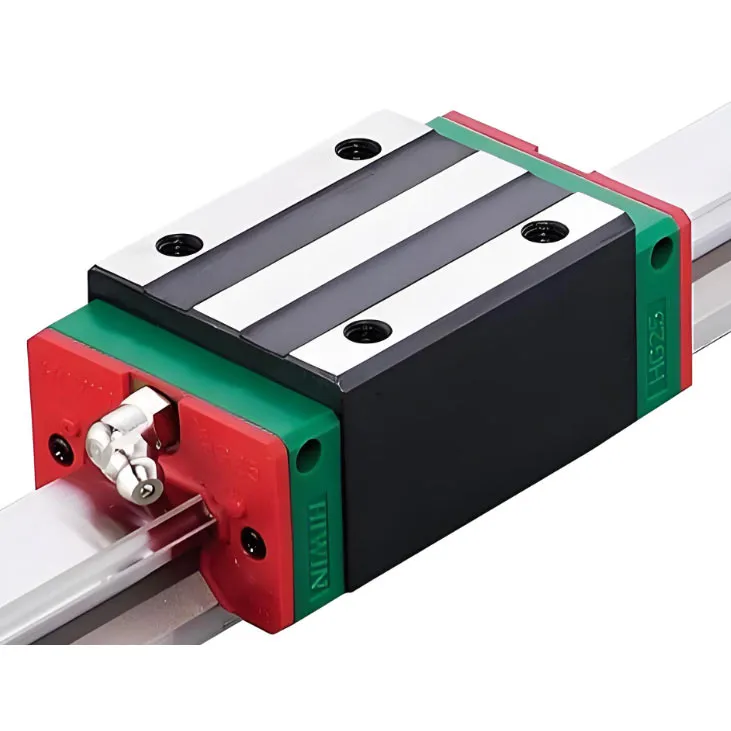

Guide Linear Features

1. High precision control

Through precision machining processes such as grinding and quenching, and the design of ball/roller circulation structures, micrometer level repetitive positioning accuracy can be achieved. Optimization of ball components, eliminates motion lag and improves smooth operation.

2. Low friction and high efficiency

Using rolling friction ,energy consumption is reduced by more than 60% compared to sliding friction, and high-speed motion is supported .

3. High rigidity load capacity

The four column ball/roller layout and preloading adjustment technology can withstand composite loads (radial, axial, moment), and static loads can reach hundreds of kilonewtons. There is also heavy-duty optimization, which increases the contact area of roller guides by three times and is suitable for high impact scenarios such as stamping equipment.

4. Long lifespan and reliability

Hardened steel guide rail with multi-layer sealing protection, excellent wear resistance, and a service life of tens of thousands of hours.

Anti environmental erosion, dust-proof and waterproof structure, and high/low temperature resistant materials, suitable for harsh environments such as semiconductor workshops and food machinery.

5. Modularity and adaptability

Standardized size and installation hole design, compatible with mainstream brand interfaces, supporting quick replacement and system expansion.

Compact design: micro rail slider suitable for space limited scenarios such as 3C electronics and medical equipment.

-

Guide Linear Performance Advantages

Advantage dimension

Technical Support

precise positioning

Micron level repeatability accuracy+automatic centering capability (arc groove design absorbs installation deviation)

Efficient carrying capacity

Four column ball/roller composite load distribution+reinforced end cap impact resistant structure

Dynamic adaptability

Accurately match the working condition requirements

Environmental compatibility

Multi layer sealing+self-lubricating/maintenance free design, reducing dust and oil pollution interference

-

Guide Linear Selection

Accuracy level: C3/C5/C7 accuracy corresponds to different positioning requirements;

Load type: static load (kN), dynamic load (kN), and moment (N · m) matching equipment load characteristics;

Environmental adaptation: temperature range, protection level , and lubrication method (grease lubrication/oil lubrication).

-

Guide Linear Application

Machine Centers

NC Lathes

Grinding Machines

Precision Machining Machines

Heavy Cutting Machines

Automation Devices

Transportation Equipment

Measuring Equipment

Devices Requiring High Positional Accuracy

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.