-

Product Features

Low noise design

Using synchronous coupling technology to evenly and equally arrange the balls, eliminating the sound of collision between the balls, reducing high-frequency noise by about 5 decibels, and improving the overall noise intensity in all speed ranges.

Self lubricating design

The synchronous coupling has a built-in oil storage space, which continuously provides lubrication for the steel ball during operation, reducing the frequency of replenishing lubricating oil and ensuring a long service life.

Improved smoothness of movement

All steel balls start almost simultaneously, eliminating the frictional resistance fluctuations caused by the load side steel balls moving first in traditional guide rails, and maintaining stable motion inertia.

High speed performance

The ball and synchronous coupling adopts a circular line contact design, effectively reducing frictional resistance and suitable for high-speed working conditions.

Interchangeability design

The slider and slide rail can be replaced separately to improve maintenance convenience, but the combination accuracy is slightly lower than non interchangeable models.

-

Product Application

Semiconductor equipment: low dust and silent demand scenarios.

Precision instruments: such as laser engraving machines and measuring equipment.

Automated machinery: high-speed handling, high rigidity load scenarios.

-

Product Detail

-

-

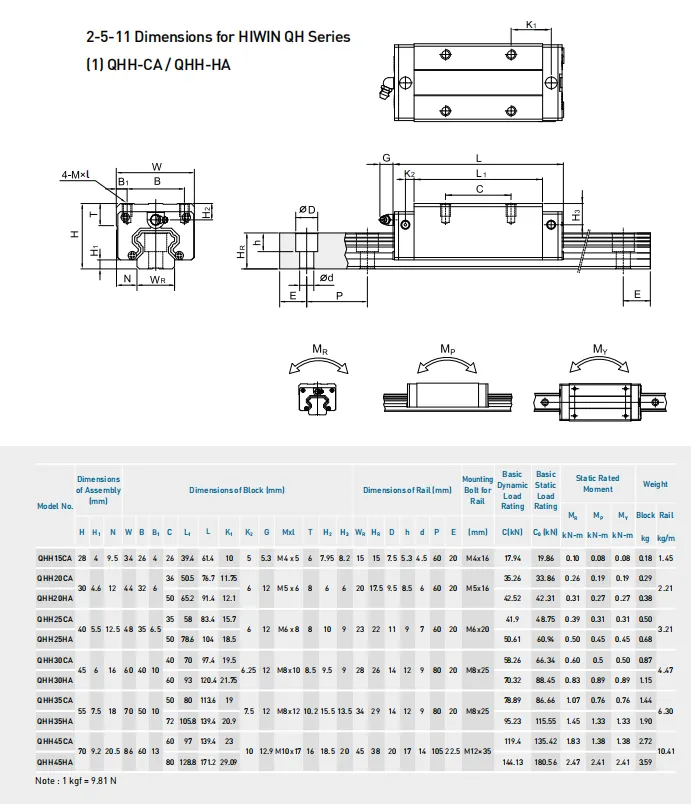

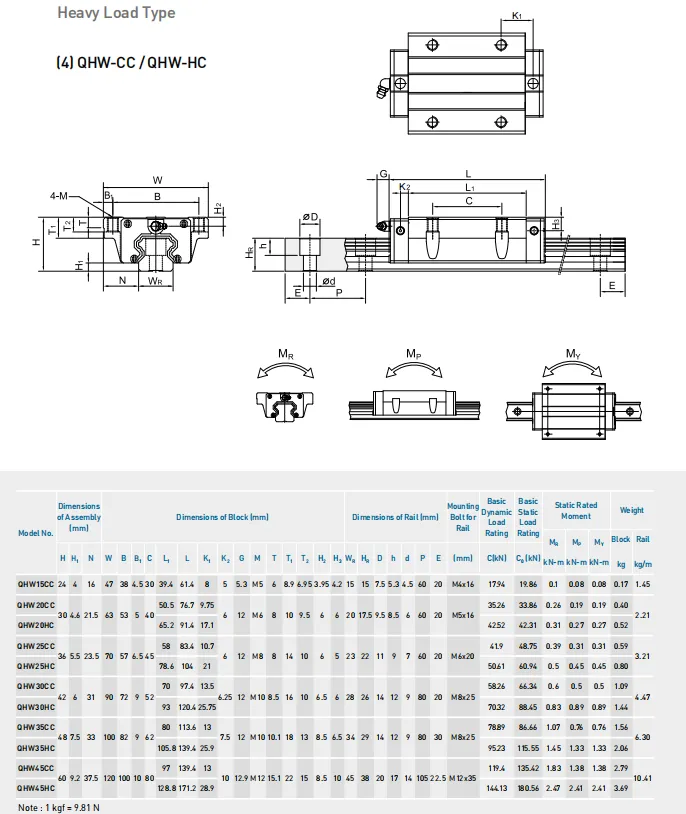

Product Parameters

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.