-

Ball Screw Spline Features

1、 High torque carrying capacity

Adopting a special structure: The outer circumferential surface of the spline shaft is equipped with three sets of 120 ° uniformly distributed rolling protrusions, each set supported by double row load-bearing steel balls, with a total of six rows of ball columns bearing the load

Pre compression design: Pre compression is applied through spline shaft bushings to eliminate clearance in the direction of rotation, significantly improving torque rigidity and deformation resistance.

2、 Compact flange structure

Integrated flange connection: saves installation space, especially suitable for space limited scenarios such as robotic arm joints and precision instruments.

Anti cantilever load: Optimize the structure to enhance its adaptability to cantilever moments and reduce the impact of unbalanced loads.

3、 Zero gap and high precision

Zero backlash in rotation direction: The preloading mechanism eliminates transmission clearance and achieves precise positioning.

Low friction rolling: Steel balls roll on precision ground tracks with minimal frictional resistance, reducing heat generation and wear.

4、 High rigidity and stability

Large contact angle design: enhances the load capacity in both radial and torque directions.

Multiple rows of ball bearings are evenly loaded: 6 rows of ball bearings distribute the load reasonably and maintain stable operation even under high-intensity impact.

-

Ball Screw Spline Application

High precision equipment: semiconductor packaging machine, SMT surface mount equipment, optical inspection instrument.

Heavy duty scenarios: industrial robot joints, wind turbine pitch systems.

Medical and Aerospace: Surgical Robots, Satellite Attitude Adjustment Mechanisms.

-

Product Detail

-

-

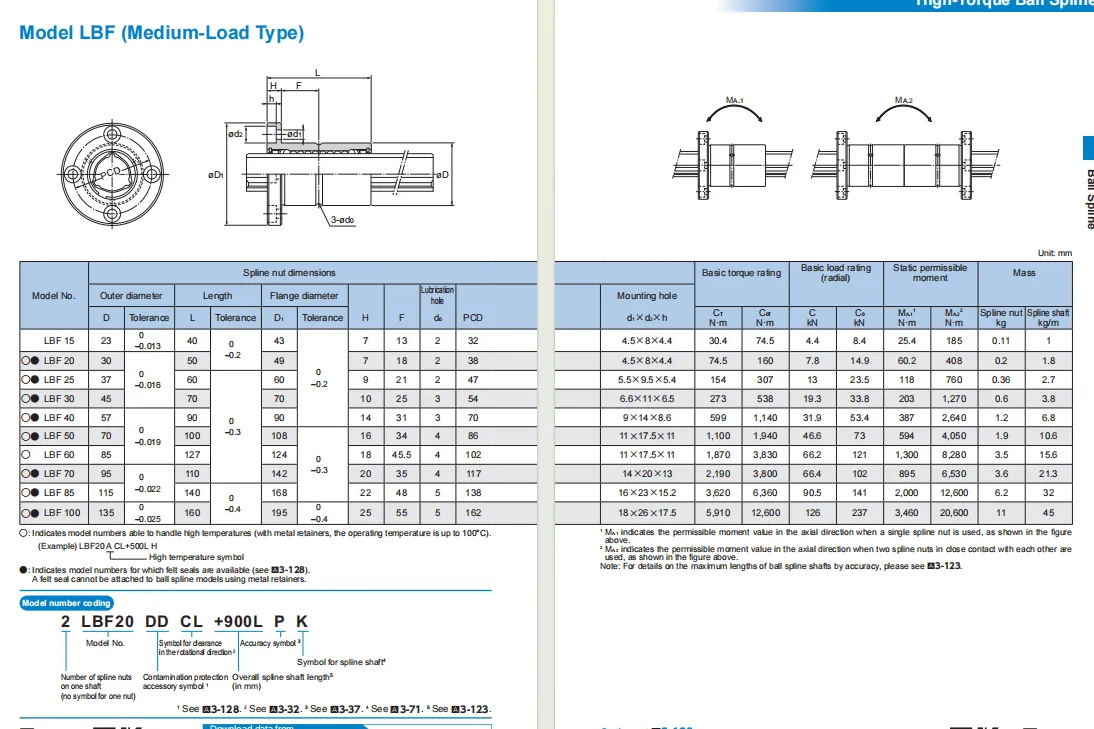

Product Parameters

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.