-

Linear Module Classification

1、Classified by transmission mode

Type

Characteristic

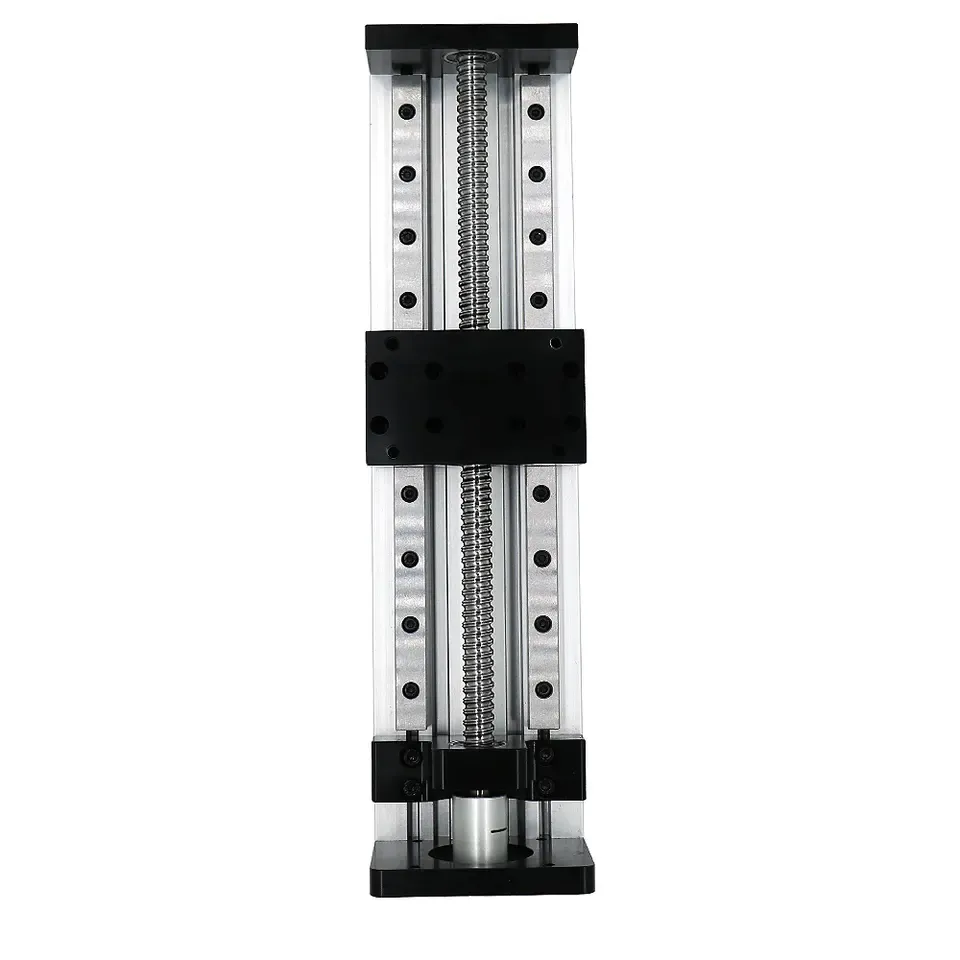

Ball screw linear module

High rigidity, low friction, strong torsional resistance

Synchronous belt linear module

Speed limit, low cost

Gear rack linear module

Suitable for low precision and heavy-duty scenarios

Linear motor module

Direct drive transmission technology achieves ultra-high precision and ultra-high speed.

2、Classified by protective structure

Type

Characteristic

Fully enclosed linear module

Stainless steel strip dustproof design, high IP protection level, supports harsh environments

Semi closed linear module

Aluminum profile integrated molding, dustproof and splash proof, easy maintenance

Open linear module

No dust-proof structure, small size, flexible installation

3、Special functional classificationion

Type

Characteristic

Modular customized linear module

Support separate supply of slide rail slider (such as KK single axis module) and load expansion components to reduce maintenance costs

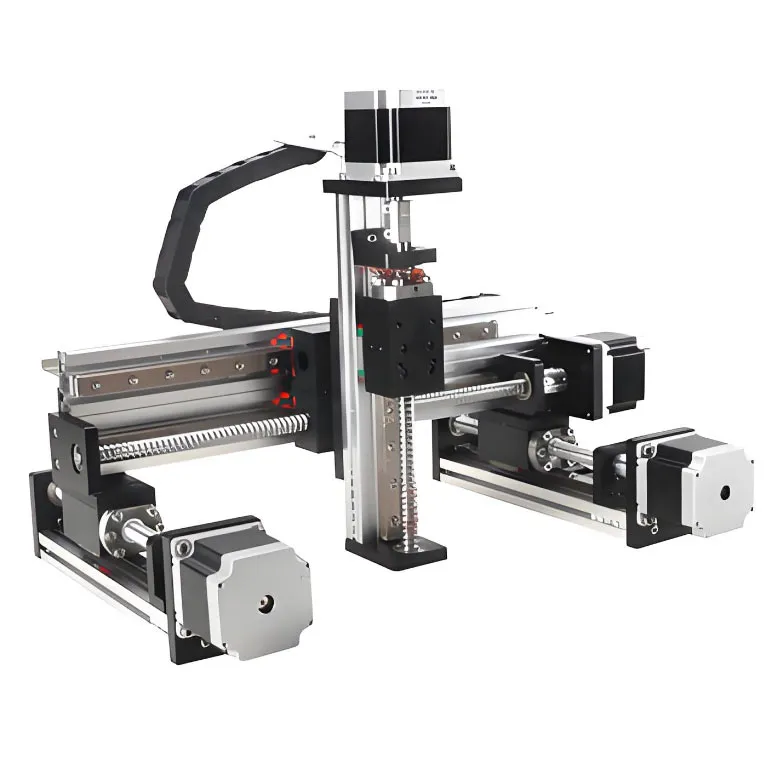

Multi axis combination linear module

Realize 3D motion through XYZ axis combination, gantry module

-

Linear Module Features

Easy to design and install

Small size and light weight

high-precision

rigidity

Fully equipped

Optimal design

-

Linear Module Performance Advantages

1. High speed response and stability

Adopting a dual axis guide rail and chrome plated axis design, it has the characteristics of low friction and high rigidity, supports frequent start stop and smooth operation, and has lower noise than traditional transmission devices.

2、 Protection and Durability

Fully enclosed dust-proof technology, the new module uses sealing tape and contact components to effectively prevent external dust from entering the interior of the base, and automatically cleans up attached dust during movement, extending the service life of the equipment

3. Corrosion and rust resistance characteristics

The aluminum alloy material slider and axis support seat are treated with anodizing, and the axis is plated with hard chromium, which has both rust prevention and corrosion resistance, and is suitable for harsh industrial environments.

4. Customized modular design

The slide rail and slider can be supplied separately, and the worn parts support complete interchangeability, reducing maintenance complexity and costs in the later stage.

5. High cost-effectiveness

Compared to linear motors, linear modules adopt standardized structural design, with lower production costs, and can expand load capacity through rigid guide rails, covering light to heavy load scenarios.

-

Linear Module Application

CNC machining equipment

Robot Integration

AOI optical inspection equipment

Automatic soldering machine, surface mount machine

New energy and power equipment

medical equipment

Automobile and Heavy Equipment Manufacturing

Logistics and Warehouse Automation

-

Linear Module Selection

1、 Core performance parameters

Load: dynamic load, static load

Maximum speed: Synchronous belt module can reach 5m/s (such as GTB series), ball screw module is usually ≤ 1.5m/s

Effective travel: Requires 10-15% over travel protection distance to avoid mechanical limit collisions

2.、Body size and material

Module width: determines load capacity

Installation length: needs to match effective travel and mechanical limit space

Sliding block type: flange type (flat width design) or square type (high rigidity design)

Protection level: Fully enclosed module>Semi enclosed module>Open module

3、 Environmental adaptation parameters

Temperature compensation: Precision scenes require the configuration of grinding grade screw rods

Corrosion resistance: anodized aluminum+chrome plated shaft, suitable for acidic and alkaline environments

Dustproof design: stainless steel sealing tape+automatic dust cleaning structure (suitable for dust-free workshops)

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.