In the realm of linear motion technology, gear and rack systems stand as fundamental components, enabling smooth, controlled movement in countless industrial applications. From machinery to automation, these systems convert rotational motion into linear motion, powering everything from manufacturing lines to precision equipment. Among the key players in this field are rocket pinion designs and rack and pinion setups, each tailored to specific performance needs. Behind these high-quality components lies the expertise ofour company Import and Export Trading Company Ltd, a leader in linear motion solutions. In this article, we will explore the world of gear and rack systems, highlight the precision of rocket pinion technology, and showcase how our company’s commitment to quality and innovation elevates these essential components.

Gear and Rack Systems: The Foundation of Linear Motion

Gear and rack systems are the workhorses of linear motion, consisting of a gear (a rotating wheel with teeth) and a rack (a linear bar with matching teeth). When the gear turns, its teeth mesh with the rack, converting rotational motion into straight-line movement—a mechanism critical for applications requiring accuracy and reliability. Atour company Import and Export Trading Company Ltd, established in 2020, we specialize in perfecting such systems, ensuring they meet the rigorous demands of modern industry.

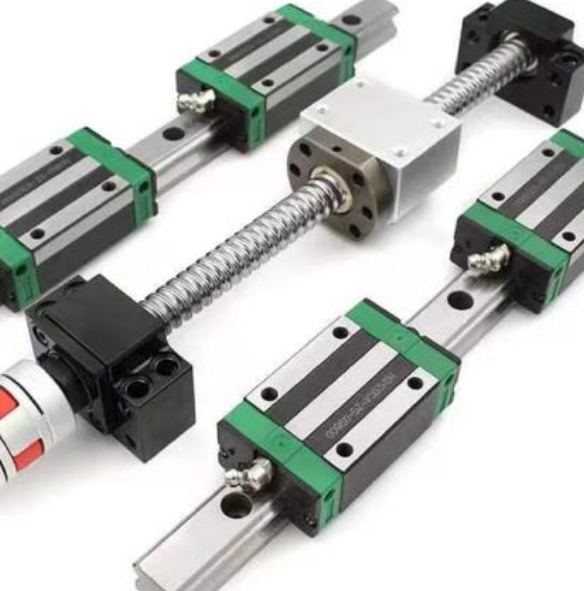

As a professional factory specializing in ball screws, linear guides, single-axis linear actuators, ball splines, and bearings,our company brings unparalleled expertise to gear and rack production. Our gear and rack systems are engineered with precision, leveraging advanced manufacturing techniques to ensure seamless meshing, minimal friction, and long-lasting performance. Whether for heavy-duty industrial machinery or delicate automation equipment, our gear and rack solutions are designed to deliver consistent results, backed by our commitment to quality.

We are proud to offer OEM and ODM customized services, tailoring gear and rack systems to the unique needs of each customer. This flexibility allows us to support a wide range of industries, from automotive to aerospace, ensuring that every application receives a motion solution perfectly suited to its requirements.

Rocket Pinion: Precision Engineering Powered byour company’s Expertise

A rocket pinion is a specialized type of gear designed for high-performance applications where precision and durability are non-negotiable. Unlike standard pinions, rocket pinion designs often feature enhanced tooth profiles, reinforced materials, and tight tolerances, making them ideal for systems requiring rapid movement, heavy loads, or minimal backlash. Atour company, we take pride in our ability to produce rocket pinion components that meet these exacting standards, thanks to our state-of-the-art facilities and skilled team.

Our cooperative factory team of 100 employees, with senior technicians accounting for more than 30%, brings decades of combined experience to rocket pinion production. These experts oversee every step of the manufacturing process, from design to finishing, ensuring that each rocket pinion meets our strict quality benchmarks. To guarantee precision, we have imported advanced equipment from Germany and Japan, which enables high-efficiency production and stable quality control. This investment in technology ensures that our rocket pinion components consistently outperform in even the most demanding environments.

Whether integrated into automation systems or heavy machinery, our rocket pinion products embody our core values of innovation, quality, and reliability. They are a testament to our mission to deliver excellence in every component we produce.

Rack and Pinion: Versatility in Motion, Backed by our company’s Commitment

The rack and pinion system is celebrated for its versatility, finding use in everything from conveyor belts to steering mechanisms. What makes rack and pinion setups indispensable is their ability to provide precise linear motion over long distances, with minimal maintenance requirements. At our company, we have honed our rack and pinion production to meet the diverse needs of global industries, ensuring that each system is built to last and perform.

Our rack and pinion systems are designed with adaptability in mind, allowing for easy integration into existing machinery. We offer a range of configurations, from standard sizes to custom designs, all crafted from high-quality materials that resist wear and corrosion. This focus on durability is why our rack and pinion products are exported to over 50 countries worldwide, including Germany, the United States, Canada, France, and Japan, where they are trusted by manufacturers and engineers alike.

Central to our rack and pinion success is our customer-centric approach. We continuously strive to enhance product performance and technical levels, working closely with clients to understand their unique challenges. Whether a customer needs a rack and pinion system for high-speed automation or heavy-load applications, our team collaborates to develop solutions that exceed expectations. This dedication to customization and service has made us a leading provider of rack and pinion systems in the global market.

Elevating Gear and Rack Technology Through Innovation and Quality

|

Strengths in Gear and Rack Production |

Description |

|

Expert Team |

100 employees, 30% senior technicians with deep industry experience |

|

Advanced Equipment |

Imported machinery from Germany and Japan for precision manufacturing |

|

Customization |

OEM and ODM services to tailor gear and rack systems to client needs |

|

Global Reach |

Products exported to 50+ countries, trusted by international markets |

|

Quality Focus |

Strict quality control at every stage, from design to delivery |

FAQS about Exploring our company’s Gear and Rack Solutions

What Materials Are Used In Your Gears And Racks?

Our gears and racks are typically made from high-quality materials such as stainless steel, carbon steel, alloy steel, or engineering plastics, depending on the application requirements. Material choice ensures durability, strength, and precision.

Are Your Gears And Racks Customizable?

Yes, we offer customization options for gear modules, dimensions, tooth profiles, and materials to meet your specific design or application needs.

What Applications Are Your Gears And Racks Suitable For?

Our gears and racks are widely used in automation systems, CNC machinery, robotics, elevators, and industrial equipment where linear motion or torque transfer is required.

How Do I Select The Right Gear And Rack For My Project?

To choose the right gear and rack, consider factors such as load capacity, speed, accuracy requirements, environmental conditions, and space constraints. Our engineering team can assist with proper selection and design support.

What Standards Do Your Gears And Racks Comply With?

As a professional gear and rack manufacturer, our products are manufactured to comply with international standards such as DIN, ISO, or AGMA, ensuring high precision and reliability in industrial applications.

At our company Import and Export Trading Company Ltd, we believe that precision motion technology is the backbone of industrial progress—and our gear and rack, rocket pinion, and rack and pinion systems are built to drive that progress forward. With a focus on innovation, quality, and customer collaboration, we are proud to be a global leader in linear motion solutions. We invite you to visit our website to see firsthand our manufacturing facilities, meet our expert team, and explore how our products can elevate your operations. Whether you need standard components or customized solutions, we are here to collaborate, innovate, and create a better future together. Contact us today to start your journey with a partner you can trust.