Delivering Precision: An In-Depth Look at Micro Bearing Linear Guides

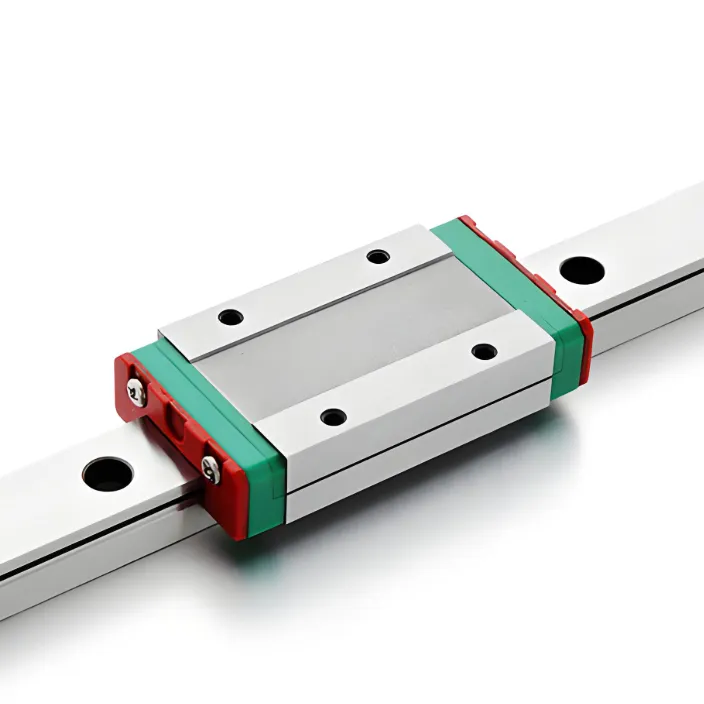

In the demanding landscape of modern industrial automation, the pursuit of miniaturization, high precision, and robust durability is constant. Micro linear motion components are pivotal in achieving these objectives, particularly in compact and high-speed applications. Among these, the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails stands out as a superior solution. Engineered for environments where space is at a premium but accuracy cannot be compromised, these guides facilitate smooth, accurate, and reliable linear movement in a multitude of advanced machinery. This comprehensive guide delves into their technical intricacies, manufacturing excellence, diverse applications, and the inherent value they bring to precision engineering.

Industry Trends and the Demand for Miniaturization

The global automation industry is experiencing a significant shift towards compact and high-performance systems. This trend is driven by factors such as the rise of portable medical devices, smaller semiconductor manufacturing equipment, precision laboratory instruments, and compact robotics. Consequently, the demand for micro linear motion components, including MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails, is escalating. These components offer exceptional load capacity relative to their size, quiet operation, and low friction, making them ideal for applications requiring fine control and minimal energy consumption. The market forecasts indicate continued robust growth in micro-mechanisms, underscoring the strategic importance of advanced linear guide technologies.

Moreover, the increasing adoption of Industry 4.0 principles necessitates components that can withstand continuous operation, offer high repeatability, and integrate seamlessly into smart manufacturing environments. Stainless steel construction, characteristic of the MG series, addresses critical industry requirements such as corrosion resistance in harsh environments and maintains structural integrity over extended operational cycles. This material choice significantly extends the lifespan of machinery, reducing maintenance overheads and total cost of ownership for businesses investing in high-precision equipment.

Manufacturing Process and Quality Assurance

The production of MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails involves a meticulous multi-stage process, ensuring the highest standards of precision and durability. It begins with the careful selection of high-grade stainless steel, typically AISI 440C for its exceptional hardness and corrosion resistance, or similar proprietary alloys optimized for linear motion. The manufacturing journey encompasses several critical phases:

- Material Preparation & Rough Machining: Raw stainless steel billets undergo initial shaping, often through forging or hot rolling, to achieve a near-net shape, followed by rough CNC machining to prepare for precision operations.

- Precision Grinding & Lapping: This is the most critical stage. The raceway surfaces, where the ball bearings travel, are ground and then lapped to sub-micron tolerances. This ensures the guide's straightness, parallelism, and minimal friction. Advanced grinding machines with automated feedback systems maintain consistent quality.

- Heat Treatment: Components undergo specialized heat treatment processes, such as quenching and tempering, to achieve optimal hardness (typically HRC 58-62) and wear resistance, crucial for the longevity of the linear guides.

- Surface Treatment: While stainless steel offers inherent corrosion resistance, some manufacturers apply additional passivation or specialized coatings to enhance protection against specific chemicals or environments, further extending the operational life.

- Assembly & Lubrication: The precision-ground rails are then assembled with the corresponding miniature carriages, loaded with high-precision steel balls, and pre-lubricated with specific low-friction greases suitable for micro applications.

- Rigorous Inspection & Testing: Each guide undergoes stringent quality control checks, adhering to international standards such as ISO 12090 and ANSI B5.45. This includes dimensional accuracy (using CMMs), straightness, parallelism, running accuracy, preload, and friction testing. Only components meeting these tight specifications are cleared for dispatch.

This meticulous process, from raw material to final inspection, guarantees that the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails deliver superior performance, long service life, and reliable operation in demanding industrial settings. The use of stainless steel inherently provides excellent resistance to corrosion and allows for operation in various challenging environments.

Technical Specifications: MGN7 & MGN9 Series

The MG series linear guides are renowned for their compact design and high precision. The MGN7 and MGN9 variants refer to specific sizes, with the number indicating the rail width in millimeters (7mm and 9mm respectively), offering different load capacities and form factors suitable for varying application demands. Below is a detailed table outlining typical parameters for these popular models.

| Parameter | MGN7 | MGN9 | Unit |

|---|---|---|---|

| Rail Width | 7 | 9 | mm |

| Block Width | 17 | 20 | mm |

| Basic Dynamic Load Rating (C) | 1.35 - 1.96 | 2.55 - 3.73 | kN |

| Basic Static Load Rating (C0) | 1.57 - 2.16 | 3.33 - 4.51 | kN |

| Accuracy Grades | Normal, High, Precision, Super Precision, Ultra Precision | - | |

| Preload Options | Light, Medium, Heavy | - | |

| Material | Stainless Steel (AISI 440C equivalent) | - | |

| Operating Temperature Range | -20°C to +80°C | °C | |

These specifications highlight the robust design and engineering precision embedded in every MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails. The varying load ratings and accuracy grades allow for tailored selection based on the specific requirements of the target application, ensuring optimal performance and longevity.

Key Technical Advantages

High Precision and Accuracy

The core strength of the MG series lies in its exceptional precision. Designed with two rows of balls making contact with the raceway, these guides provide optimal contact angle, ensuring uniform load distribution and minimized elastic deformation. This structural integrity translates into superior positioning accuracy, repeatability, and dynamic stability, essential for delicate operations in semiconductor manufacturing, optical alignment, and medical diagnostics. The exacting manufacturing tolerances result in virtually zero backlash, critical for achieving micron-level movements.

Corrosion Resistance and Durability

Constructed entirely from stainless steel, the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails offer inherent resistance to rust and corrosion, making them suitable for use in humid, wet, or chemically aggressive environments where standard carbon steel guides would quickly degrade. This includes applications in clean rooms, food processing, and certain chemical and pharmaceutical industries. The robust material also contributes to an extended service life, reducing the need for frequent replacements and lowering operational costs over the equipment's lifespan.

Compact Design and Easy Integration

The miniature profile of the MGN7 and MGN9 series is a significant advantage for designers facing strict space constraints. Despite their small size, they maintain high load-carrying capacities, thanks to optimized ball circulation paths and rigid block designs. The standard mounting hole patterns and lightweight nature simplify integration into existing or new machine designs, reducing overall system complexity and assembly time. Their low friction coefficient also leads to higher energy efficiency, contributing to sustainable industrial practices.

Diverse Application Scenarios

The versatility and precision of MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails make them indispensable across a broad spectrum of high-tech industries. Their ability to deliver accurate linear motion in compact spaces positions them as a critical component in the following sectors:

- Semiconductor Manufacturing: Used in wafer handling robots, inspection equipment, and wire bonders where extreme precision and cleanliness are paramount.

- Medical and Laboratory Automation: Essential for analytical instruments, DNA sequencing machines, robotic surgical tools, and automated pipetting systems due to their precise movement and sterile material properties.

- Optical and Imaging Systems: Employed in cameras, microscopes, laser cutting machines, and other optical alignment devices where consistent and accurate positioning is vital for image clarity and processing.

- Printing and Packaging Machinery: Facilitate precise print head movement in 3D printers, small-scale industrial printers, and automated packaging lines requiring delicate product handling.

- Miniature Robotics and Automation Cells: Provide accurate linear movement for robotic arms, pick-and-place units, and other small-scale automation solutions.

- Aerospace and Defense: Used in specialized testing equipment and miniature actuators where reliability and performance in demanding conditions are crucial.

The robust stainless steel construction also means these guides can function reliably in environments with moisture or corrosive agents, expanding their utility beyond typical dry industrial settings. This adaptability makes them a preferred choice for engineers designing next-generation precision equipment.

Manufacturer Comparison and Selection Criteria

When selecting MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails for critical applications, choosing the right manufacturer is as important as selecting the right product specifications. Key criteria for evaluating suppliers include:

- Expertise and Experience: Look for manufacturers with a proven track record in precision motion control, particularly in miniature components. Years of service and specific case studies demonstrate deep industry knowledge.

- Quality Certifications: Adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management indicates a commitment to consistent, high-quality production. Specific product certifications or compliance for regulated industries (e.g., medical) are also crucial.

- Customization Capabilities: For unique applications, the ability to provide tailored rail lengths, block configurations, or specialized coatings is invaluable.

- Technical Support and Engineering Assistance: A responsive support team that can assist with design integration, troubleshooting, and performance optimization adds significant value.

- Global Reach and Supply Chain Reliability: Manufacturers with well-established distribution networks ensure timely delivery and consistent product availability, crucial for continuous production lines.

- Customer Feedback and Testimonials: Positive reviews and long-term customer relationships are strong indicators of a manufacturer's trustworthiness and product reliability.

By thoroughly evaluating these factors, buyers can ensure they partner with a manufacturer capable of delivering not just components, but comprehensive solutions that meet their exact requirements and uphold the highest standards of performance and reliability.

Customization Solutions and Application Cases

Tailored for Unique Demands

While standard MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails meet most industrial needs, many advanced applications require highly specific configurations. Leading manufacturers offer comprehensive customization services, allowing engineers to optimize linear guide performance for their precise requirements. This can include:

- Custom Rail Lengths: Precise cutting to exact lengths, often with end-machining for seamless integration.

- Surface Treatments: Specialized coatings for enhanced corrosion resistance in extreme environments, or low-friction coatings for cleanroom applications.

- Preload and Accuracy Grades: Tailored preload settings (e.g., lighter for minimal friction, heavier for rigidity) and custom accuracy grades beyond standard offerings.

- Block Configurations: Different block types (e.g., flanged, square) or specific mounting hole patterns to fit unique machine designs.

- Lubrication Options: Pre-lubrication with specific greases for high-temperature, vacuum, or cleanroom environments.

Real-World Application Examples

The versatility of these linear guides is best illustrated through their successful deployment in demanding real-world scenarios:

- Automated Microscope Stages: An MGN7 system was integrated into an advanced research microscope, enabling sub-micron level positioning for automated cell analysis. Its compact size allowed for a smaller, more precise stage, while the stainless steel ensured stability in humidity-controlled lab environments.

- Portable DNA Sequencers: MGN9 guides provided the critical linear motion for the fluidic handling and optical detection modules in a new generation of portable DNA sequencers. The guides' low friction and high repeatability were essential for accurate sample processing, contributing to faster and more reliable diagnostic results in the field.

- Precision Engraving Machines: In a high-speed laser engraving system for jewelry, the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails ensured the precise and smooth movement of the laser head. This allowed for intricate designs with exceptional detail and consistency, even under continuous operation.

Ensuring Trust: Warranty, Support, and FAQs

Establishing trust with B2B clients goes beyond product specifications; it encompasses comprehensive support and reliability assurances. When investing in MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails, consider the following:

Warranty and Quality Assurance

Reputable manufacturers typically offer a robust warranty, often ranging from 12 to 24 months, covering defects in materials and workmanship. This commitment is backed by strict quality management systems (e.g., ISO 9001 certified processes) and rigorous testing protocols before products leave the facility. Consistent adherence to international precision standards ensures that every unit performs as expected, providing peace of mind to integrators and end-users.

Delivery Cycle and Logistics

Efficient global logistics and a streamlined supply chain are crucial for timely project completion. Manufacturers with well-managed inventory and established distribution networks can offer competitive delivery times, often ranging from 1-2 weeks for standard products and 3-5 weeks for customized orders, depending on complexity. Clear communication regarding lead times and shipping updates is vital for effective project planning.

Customer Support and Technical Assistance

Access to expert technical support is invaluable. This includes assistance with product selection, installation guidance, troubleshooting, and maintenance advice. A dedicated support team capable of offering immediate responses and in-depth engineering consultations can significantly reduce downtime and optimize system performance, fostering long-term partnerships.

Frequently Asked Questions (FAQs)

- Q: Can MG series guides be used in vacuum environments?

A: While the stainless steel construction is suitable, specific vacuum-compatible greases and surface treatments might be required. Consult with the manufacturer for ultra-high vacuum applications. - Q: What is the expected service life?

A: Service life is calculated based on load, speed, lubrication, and environmental factors. For properly sized and maintained MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails, a lifespan of 5,000 to 10,000 km of travel is common, with some reaching much higher under ideal conditions. - Q: Are these guides suitable for high-speed applications?

A: Yes, their low friction and stable design allow for high-speed operation, typically up to 3-5 m/s depending on the specific model and load. - Q: How do I select the correct preload?

A: Preload selection depends on the application's required rigidity, vibration damping, and precision. Light preload is for minimal friction, medium for balanced performance, and heavy for high rigidity and shock loads. Technical consultation is recommended.

Conclusion and Future Outlook

The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails represent the pinnacle of miniature linear motion technology, offering an unparalleled combination of precision, durability, and compact design. Their stainless steel construction ensures reliable performance in diverse and challenging environments, from sterile medical labs to demanding industrial automation cells. As industries continue their drive towards miniaturization, higher throughput, and enhanced efficiency, the demand for such advanced components will only intensify. Investing in high-quality linear guides is not merely a component purchase; it is a strategic decision that underpins the reliability, precision, and longevity of the entire machinery, directly impacting operational success and competitive advantage in the global market.

References

- Modern Manufacturing Technology Journal. "Advances in Precision Linear Motion Systems for Micromanufacturing." Vol. 45, No. 3, 2022, pp. 112-128.

- Journal of Applied Mechanics and Materials. "Corrosion Resistance and Fatigue Life of Stainless Steel in Micro Linear Bearings." Vol. 987, 2023, pp. 345-352.

- International Robotics and Automation Review. "Miniature Linear Guides in Compact Robotic Systems: A Performance Analysis." Vol. 18, No. 1, 2024, pp. 55-68.

- Precision Engineering Quarterly. "Impact of Preload on the Accuracy and Stiffness of Micro Linear Guideways." Vol. 7, No. 2, 2023, pp. 89-101.