The Imperative of Precision: An Overview of MG Series Micro Bearing Linear Guides

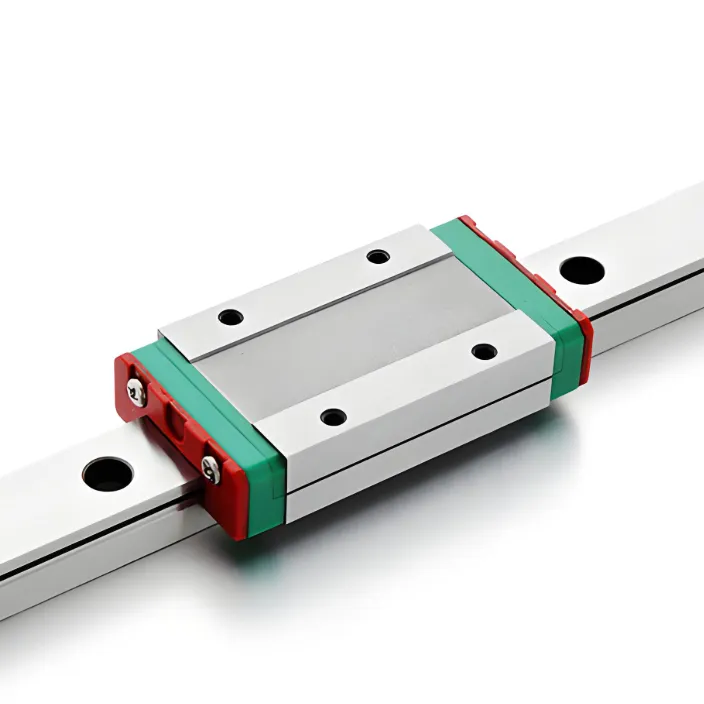

In the realm of modern industrial automation and precision engineering, the demand for compact, high-performance motion solutions is constantly escalating. This includes applications ranging from intricate medical devices to advanced semiconductor manufacturing equipment. At the forefront of meeting this critical need are micro bearing linear guides, engineered to deliver unparalleled accuracy and smooth motion in confined spaces. The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails represent a pinnacle in this category, offering a robust and reliable solution for highly sensitive and corrosive environments. Their compact design, combined with superior material properties, makes them indispensable for next-generation machinery requiring miniature, high-precision linear motion. This article delves into the technical specifications, manufacturing intricacies, and diverse applications of these essential components, providing insights for technical professionals and B2B decision-makers seeking optimal motion control solutions.

The drive for miniaturization without compromising performance defines current industry trends. As machines become smaller and more integrated, every component must contribute significantly to overall system efficiency and reliability. The MG Series, particularly the MGN7 and MGN9 models, addresses this by providing exceptional load capacity and rigidity within a reduced footprint. This allows designers to achieve higher densities of functionality, leading to more compact and sophisticated end-products. Understanding the nuanced technical advantages and application-specific benefits of these guides is crucial for their effective integration into complex systems, ensuring long-term operational excellence and minimal maintenance requirements.

Unpacking the Technical Parameters of MGN7 and MGN9 Linear Guides

The performance of any linear guide is defined by a precise set of technical parameters, which dictate its suitability for specific applications. For the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails, critical specifications include basic dynamic load rating (C), basic static load rating (C0), and various moment load ratings (MR, MP, MY). These parameters, often derived from rigorous testing adhering to ISO 12090-2 standards, provide a quantitative measure of the guide's ability to withstand forces during both motion and at rest. For instance, the basic dynamic load rating refers to the constant load and direction under which 90% of a group of identical linear guides will run for a distance of 50 km without showing signs of material fatigue. The static load rating, conversely, indicates the maximum non-moving load the guide can endure without incurring permanent deformation that would impair its function.

Accuracy grades are another vital aspect, typically ranging from normal to precision (P), super precision (SP), and ultra precision (UP). These grades relate to the permissible dimensional tolerances and the running parallelism of the guide rail and block assembly. For high-precision applications, minimizing deviation is paramount, making higher accuracy grades essential. Preload, referring to an internal force applied during assembly, significantly enhances rigidity and reduces clearance, thereby improving motion accuracy and minimizing vibration. The MG Series guides are engineered to offer optimal preload options, ensuring stable and repeatable motion profiles. Below is a representative table outlining typical specifications for MGN7 and MGN9 models, emphasizing their robust capabilities.

| Parameter | MGN7 (Typical) | MGN9 (Typical) |

|---|---|---|

| Rail Width (mm) | 7 | 9 |

| Block Height (mm) | 6.5 - 8.5 | 8 - 10.5 |

| Basic Dynamic Load (C) (N) | ~900 - 1200 | ~1500 - 2000 |

| Basic Static Load (C0) (N) | ~1400 - 1800 | ~2500 - 3200 |

| Accuracy Grades | N, H, P, SP, UP | N, H, P, SP, UP |

| Material | Stainless Steel | Stainless Steel |

| Operating Temperature (°C) | -20 to +80 | -20 to +80 |

The Advanced Manufacturing Process Behind MG Series Linear Guides

The superior performance of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails is rooted in an meticulously controlled manufacturing process, combining advanced material science with precision engineering. The journey begins with the selection of high-grade stainless steel, typically AISI 440C or equivalent, known for its exceptional corrosion resistance, hardness, and wear resistance—critical properties for demanding industrial environments. This material choice is pivotal, particularly in applications exposed to moisture, chemicals, or medical fluids, ensuring a significantly extended service life compared to standard carbon steel alternatives.

The manufacturing sequence involves several key stages. Initially, raw stainless steel bars undergo precision cutting and forming to approximate the final rail and block geometries. This is followed by a rigorous heat treatment process, which enhances the material's structural integrity and surface hardness. Subsequent stages involve sophisticated CNC (Computer Numerical Control) machining, where the raceways and mounting holes are milled to extremely tight tolerances. This CNC precision is paramount for achieving the required running parallelism and accuracy grades. For instance, achieving a parallelism tolerance of mere micrometers across the rail length is a testament to the advanced machining capabilities employed.

Post-machining, surfaces undergo precision grinding and polishing to achieve a mirror-like finish, crucial for minimizing friction and ensuring smooth ball bearing circulation. The final assembly involves careful integration of the stainless steel balls and retainers into the guide blocks, often under cleanroom conditions to prevent contamination. Every step is rigorously controlled and monitored against international standards such as ISO 9001 for quality management and relevant ANSI/ABMA standards for bearing design and performance. In-process and final inspections include dimensional checks, hardness testing, surface roughness measurement, and functional tests for running smoothness and load deflection. This meticulous process ensures that each MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails unit not only meets but often exceeds the stringent performance expectations for its intended applications. The inherent corrosion resistance of stainless steel makes these guides exceptionally suitable for environments where exposure to corrosive elements is a concern, such as in certain food processing or medical equipment.

Key Technical Advantages and Market Positioning

The inherent advantages of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails position them as a leading choice for demanding precision applications. Firstly, their stainless steel construction provides exceptional corrosion resistance, making them ideal for use in wet, humid, or chemically aggressive environments where standard steel guides would quickly degrade. This includes applications in medical diagnostic equipment, pharmaceutical manufacturing, and certain food processing lines. The choice of stainless steel also means these guides can be easily cleaned and sterilized, a critical feature for hygienic industries.

Secondly, the compact and lightweight design of the MGN7 and MGN9 models offers a significant advantage in applications with limited space. Despite their miniature size, they deliver remarkable load capacities and high rigidity, achieved through optimized raceway designs and precise ball circulation. This high stiffness ensures minimal deflection under load, maintaining positional accuracy and repeatability, which is crucial for intricate operations such as micro-assembly or optical scanning. Their low friction coefficient, inherent to recirculating ball systems, translates into smooth, consistent motion with minimal driving force required, indirectly contributing to energy efficiency in automated systems.

Compared to traditional sliding guides, the rolling element design of the MG Series significantly reduces wear and extends operational life, translating into lower maintenance costs and reduced downtime. While sliding guides rely on direct contact and lubrication for motion, recirculating ball guides provide virtually frictionless movement, ensuring superior long-term performance and minimal stick-slip. This technological edge, combined with adherence to strict quality control protocols like ISO 9001 certification, underscores the reliability and performance commitment of manufacturers providing MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails. When considering a manufacturer, evaluating their certification, track record, and specific testing data is crucial for ensuring the quality and longevity of the linear guides.

Industry Trends and Diverse Application Scenarios

The global linear motion market continues to expand, driven by increasing automation across various sectors. Current trends highlight a growing demand for miniaturized components that can deliver high precision and reliability in increasingly compact designs. This precisely aligns with the capabilities of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails. Industries such as medical technology, where devices are becoming smaller and more complex, heavily rely on these miniature guides for precise positioning of optical elements, fluidic pumps, and robotic surgical tools. Similarly, in semiconductor manufacturing, the need for sub-micron accuracy in wafer handling and inspection equipment makes the MG Series indispensable for achieving stringent process control.

Beyond these high-tech sectors, these linear guides find extensive use in advanced manufacturing processes. For instance, in 3D printing, they enable precise and smooth movement of the print head, directly influencing the accuracy and surface finish of the printed object. In small-scale CNC milling machines or laser engraving systems, their compact size allows for the development of desktop-sized precision equipment. Laboratory automation, including sample analysis and dispensing systems, also benefits significantly from the compact design and corrosion resistance offered by the stainless steel construction. The versatility and robust performance of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails empower engineers to push the boundaries of design and functionality in numerous application areas.

Furthermore, the ongoing integration of robotics into smaller spaces, from collaborative robots to specialized pick-and-place units, necessitates linear motion components that are both compact and highly accurate. The MG Series serves as a foundational element in such robotic arms and end-effectors, facilitating delicate and repetitive movements with consistent precision. The ability to customize rail lengths, block configurations (e.g., flanged or non-flanged), and preloads allows for seamless integration into diverse machine designs, optimizing performance for specific load and speed requirements. This adaptability ensures that the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails will remain a vital component in the evolution of precision automation.

Tailored Solutions and Exemplary Application Cases

While standard configurations of MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails meet a wide array of needs, many sophisticated applications require highly customized solutions. A reputable manufacturer understands that off-the-shelf components might not always fit the unique design constraints or performance targets of a specialized machine. This is where the ability to provide tailored rail lengths, specific surface treatments for enhanced corrosion or wear resistance, or custom block configurations becomes invaluable. For instance, in a high-vacuum environment, specific lubrication might be required, or a particular mounting pattern on the guide block might be necessary for seamless integration with a custom stage.

Consider a real-world application in a cutting-edge ophthalmic surgical robot. This robot requires extremely smooth, precise, and vibration-free motion for delicate eye procedures. The compact footprint of the MGN7 linear guides allows for the miniaturization of the robotic arm, enabling surgeons to operate with unprecedented precision. The stainless steel construction ensures biocompatibility and resistance to sterilization agents, crucial for medical environments. The high running parallelism, typically in the range of 3-7 micrometers for SP or UP grades, guarantees the consistent positioning accuracy necessary for avoiding critical errors. In another scenario, a client developing a new generation of automated laboratory liquid handlers experienced significant issues with conventional guides corroding due to exposure to aggressive chemical reagents. By implementing custom-length MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails, they achieved not only superior corrosion resistance but also a noticeable improvement in dispensing accuracy and equipment longevity, reducing downtime by over 30% in a six-month trial.

Such success stories underscore the importance of collaborating with manufacturers who not only supply high-quality standard products but also possess the engineering expertise to provide bespoke solutions. This includes offering comprehensive technical support, application engineering advice, and flexible manufacturing capabilities to meet unique project demands. By working closely with clients, manufacturers can help optimize designs, select the most appropriate guide specifications, and ensure successful integration, ultimately delivering superior performance and long-term value in the most challenging applications.

Ensuring Trust: FAQs, Delivery, and Support

Frequently Asked Questions (FAQs)

-

Q: What is the primary advantage of stainless steel in the MG Series?

A: The primary advantage is superior corrosion resistance, making the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails ideal for applications in humid, wet, or chemically aggressive environments, including medical, food processing, and certain laboratory settings.

-

Q: How does the compact size of MGN7 and MGN9 affect performance?

A: Despite their small footprint, these guides are engineered for high load capacity and rigidity, allowing for miniaturization of machinery without compromising precision or durability. Their optimized design ensures robust performance in confined spaces.

-

Q: Are custom lengths or configurations available for specific applications?

A: Yes, reputable manufacturers typically offer customization options for rail lengths, block types (e.g., standard, flanged), and specific surface treatments or lubrication solutions to meet unique application requirements.

-

Q: What is the expected service life of these linear guides?

A: The service life depends on various factors including applied load, speed, lubrication, and environmental conditions. However, with proper selection and maintenance, the high-quality materials and precision manufacturing of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails ensure a long and reliable operational lifespan, often quantified by the 50km travel distance under rated dynamic load for 90% survival rate.

Delivery Cycle and Global Logistics

Understanding the delivery timeline is critical for project planning. Standard configurations of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails are often available for expedited shipping, with lead times typically ranging from 1-3 weeks depending on stock levels and order volume. For custom orders, the delivery cycle will vary based on the complexity of customization and production queue, generally communicated clearly during the quotation phase. Strategic global distribution networks and robust logistics partnerships ensure timely and efficient delivery to clients worldwide, minimizing project delays and supporting just-in-time inventory practices for manufacturers.

Quality Assurance and Customer Support

A strong commitment to quality is foundational. All MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails undergo stringent quality control processes, including compliance with ISO 9001:2015 standards, ensuring consistent product excellence. This commitment extends to a comprehensive warranty period, typically covering manufacturing defects for 12 to 24 months, providing peace of mind for buyers. Beyond sales, dedicated technical support teams are available to assist with product selection, installation guidance, and troubleshooting, ensuring optimal performance throughout the product's lifespan. This holistic approach to customer service underscores a commitment to long-term partnerships and client success.

Conclusion: Precision Engineering for the Future

The continuous evolution of industrial automation and high-precision machinery relies heavily on foundational components that offer uncompromising performance in miniature packages. The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails stands as a testament to this engineering philosophy, providing a robust, compact, and highly accurate solution for a myriad of demanding applications. From intricate medical devices to cutting-edge semiconductor manufacturing equipment, their ability to deliver smooth, low-friction motion with exceptional corrosion resistance makes them invaluable.

By understanding the meticulous manufacturing processes, the critical technical parameters, and the broad spectrum of applications, B2B decision-makers and technical professionals can confidently integrate these guides into their designs, ensuring long-term reliability and enhanced operational efficiency. As industries continue to miniaturize and demand higher levels of precision, the MG Series will undoubtedly remain a cornerstone of advanced motion control, propelling innovation across diverse technological landscapes.

References

- ISO 12090-2: "Rolling bearings - Linear motion rolling bearings - Part 2: Dynamic and static load ratings for linear ball bearing (type LM)".

- THK Co., Ltd. "Linear Motion Systems General Catalog".

- Hiwin Corporation. "Linear Guideway Catalog".

- Schröder, J. (2018). "Precision engineering: Fundamentals and applications". CRC Press.

- Slocum, A. H. (1992). "Precision machine design". Prentice Hall.