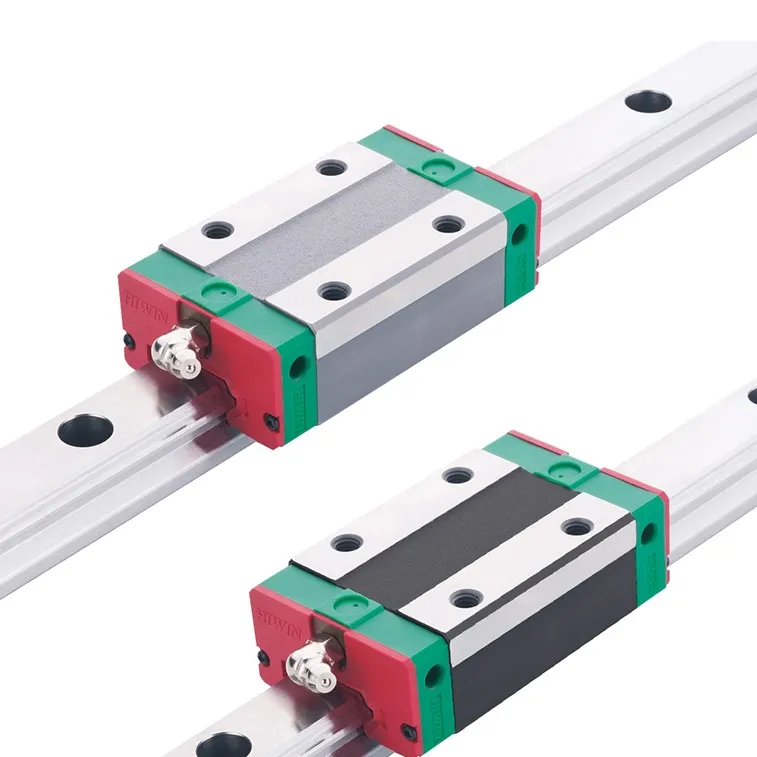

In an era where automation and precision engineering are paramount, the demand for components that deliver uncompromising accuracy and reliability has never been higher. At the forefront of this technological wave are motion control systems, with the linear guide as a cornerstone component. This comprehensive guide explores the multifaceted world of the High Quality EG Bearing Linear Guides And Linear Slider, a product engineered for superior performance in the most demanding applications.

Section 1: The Evolution of Linear Motion and Current Industry Trends

The linear motion industry is rapidly evolving, driven by the needs of Industry 4.0, IoT, and advanced manufacturing. The trend is shifting from standard components to highly specialized, intelligent motion systems. According to a market analysis by Grand View Research, the global linear motion market size is projected to reach USD 13.1 billion by 2027, expanding at a CAGR of 6.7%. This growth is fueled by increasing automation in sectors like automotive, electronics, and packaging.

Key trends shaping the landscape include:

- Miniaturization: As electronic devices and medical equipment become smaller, the demand for compact, low-profile linear guides like the EG series has surged.

- Higher Precision & Rigidity: Applications like semiconductor manufacturing and high-speed CNC machining require positioning accuracy at the sub-micron level, driving innovation in raceway geometry and preload technologies.

- Integration & Smart Technology: Modern linear guides are increasingly integrated with sensors and feedback systems for real-time performance monitoring and predictive maintenance.

- Material Science Advancements: The use of advanced alloys and surface coatings is extending the operational life and environmental resistance of linear motion components.

Our High Quality EG Bearing Linear Guides And Linear Slider is specifically designed to meet these modern demands, offering a low-profile, high-load capacity solution that excels in compact and high-precision machinery.

Section 2: Unpacking the Technical Specifications of the EG Series

Understanding the technical parameters is crucial for selecting the right linear guide. The EG series is distinguished by its low-profile design and a four-row circular arc contact structure, which provides equal load ratings in the radial, reverse-radial, and lateral directions. This design, often referred to as a "Gothic arch," minimizes contact stress and significantly enhances rigidity. Below is a detailed specification table for common models in the EG series.

| Model No. | Size | Rail Width (W) | Block Dimensions (W x H x L) | Basic Dynamic Load Rating C (kN) | Basic Static Load Rating C0 (kN) | Static Rated Moment (MR, MP, My) (kN-m) | Accuracy Grade |

|---|---|---|---|---|---|---|---|

| EGH15CA | 15 | 15 mm | 34 x 28 x 57.8 mm | 11.38 | 17.75 | 0.18, 0.15, 0.15 | N, H, P |

| EGH20CA | 20 | 20 mm | 44 x 30 x 69.8 mm | 17.65 | 27.56 | 0.36, 0.28, 0.28 | N, H, P |

| EGH25CA | 25 | 25 mm | 48 x 36 x 84.1 mm | 26.58 | 42.66 | 0.64, 0.51, 0.51 | N, H, P |

| EGH30CA | 30 | 30 mm | 60 x 42 x 99.8 mm | 38.25 | 62.76 | 1.18, 0.91, 0.91 | N, H, P |

Key Terminology Explained:

- Basic Dynamic Load Rating (C): The maximum constant load a linear guide can endure while traveling 50 km (or 100 km, depending on the standard, e.g., ISO 14728-1) at a consistent speed and direction.

- Basic Static Load Rating (C0): The maximum static load a non-moving linear guide can handle without causing permanent deformation to the raceways or rolling elements.

- Static Rated Moment (MR, MP, My): The maximum moment the slider can withstand in the roll, pitch, and yaw directions, respectively, without permanent deformation.

- Accuracy Grade (N, H, P): These grades (Normal, High, Precision) define the permissible dimensional tolerances and running parallelism of the guide, with P being the most accurate.

Section 3: The Manufacturing Journey: From Raw Steel to Precision Component

The superior performance of a High Quality EG Bearing Linear Guides And Linear Slider is not accidental; it is the result of a meticulous and controlled manufacturing process. We adhere to stringent ISO 9001:2015 quality management standards at every stage.

Detailed Manufacturing Process Flowchart:

Section 4: Core Technical Advantages of the EG Series

The EG series stands out in the competitive landscape due to a combination of intelligent design and superior manufacturing. These advantages translate directly into better performance, reliability, and value for our customers.

Low Profile & High Load Capacity

The EG series' lower assembly height and wider rail make it ideal for applications where space is limited, without sacrificing load-handling capabilities. The four-row design effectively distributes stress, allowing it to handle heavy loads from all directions.

Superior Self-Aligning Capability

The unique circular-arc groove geometry (Gothic arch) provides a self-aligning effect. This allows the slider to absorb minor installation errors in surface parallelism, simplifying setup and reducing installation costs while maintaining smooth motion.

High Rigidity & Precision

By optimizing the four-point contact design and implementing preload, we significantly increase the rigidity of the slider block. This minimizes elastic deformation under load, resulting in higher precision and repeatability, crucial for metrology and machining applications.

Global Standard Interchangeability

Our High Quality EG Bearing Linear Guides And Linear Slider are manufactured to strict dimensional tolerances. This ensures that blocks and rails can be purchased separately and are fully interchangeable with other global standard brands, offering flexibility in maintenance and system design.

Section 5: Performance Benchmark: YDMotion EG Series vs. Competitors

To provide a transparent view of our product's capabilities, we've benchmarked the YDMotion EGH20CA against a standard competitor model. The data clearly illustrates the superior engineering and material quality of our offering.

Performance Comparison: YDMotion EGH20CA vs. Competitor A

The data shows that YDMotion's High Quality EG Bearing Linear Guides And Linear Slider offers a ~7% higher dynamic load capacity and a ~6.8% higher static load capacity. More critically, our precision (P) grade models achieve a significantly better running parallelism, translating to more accurate final products for our customers.

Section 6: Customization and Tailored Solutions

We recognize that one size does not fit all. Our engineering team, with over 15 years of experience in motion control, is dedicated to providing tailored solutions. We offer a wide range of customization options for the High Quality EG Bearing Linear Guides And Linear Slider:

- Custom Rail Lengths: Rails can be cut to any specified length, with end-machining services available.

- Preload Options: We offer various preload levels (e.g., Z0, ZA, ZB) to balance between rigidity and friction for your specific application.

- Specialized Coatings: For corrosive or cleanroom environments, we provide coatings like black chrome or Raydent® treatment for enhanced protection and reduced outgassing.

- Custom Mounting Holes: Additional or custom-pattern mounting holes can be added to rails to match existing machine beds.

- Paired and Matched Sets: For applications requiring extremely high parallelism, we can provide factory-matched rail and block sets.

Section 7: Application Scenarios & Real-World Case Studies

The versatility and reliability of the EG series make it a preferred choice across a multitude of industries.

Primary Application Distribution

- CNC Machining (40%)

- Automation & Robotics (30%)

- 3D Printing & Laser Engraving (20%)

- Other (Medical, Metrology) (10%)

Case Study: Enhancing Throughput in an Automated PCB Assembly Line

Challenge:

A leading electronics manufacturer was experiencing bottlenecks in their pick-and-place robotics for PCB assembly. Their existing linear guides exhibited excessive friction and deflection at high speeds, leading to placement errors and reduced throughput. The system required a low-profile solution due to space constraints.

Solution:

Our engineers recommended replacing the existing guides with our High Quality EG Bearing Linear Guides And Linear Slider (Model EGH15CA, P-Grade with ZA preload). The low profile fit perfectly within the machine's envelope. The high rigidity and low friction of the P-grade guides allowed the robotic arm to accelerate and decelerate faster without vibration or positioning overshoot.

Results:

- 18% increase in machine cycle speed.

- 99.98% reduction in component placement errors, down from 99.8%.

- 30% reduction in maintenance downtime due to the guide's superior durability and sealing.

"Switching to YDMotion's EG series was a game-changer. The precision and speed we achieved surpassed our expectations. Their technical support during the integration process was invaluable."

- Head of Engineering, [Major Electronics Manufacturer]

Section 8: Frequently Asked Questions (FAQ)

To further enhance your understanding and confidence in our products, we've compiled answers to some common technical questions.

The rail and slider body are manufactured from high-carbon chromium bearing steel (GCr15 or its equivalent, SUJ2/100Cr6). This material is selected for its exceptional hardness, high wear resistance, and fatigue strength after heat treatment. The rolling elements (steel balls) are also made from the same material to ensure uniform performance. This choice guarantees a long operational life and consistent precision, even under heavy loads and high-duty cycles.

Preload is the internal force applied to the rolling elements to eliminate clearance and increase rigidity. The choice depends on your application's needs:

- Light Preload (ZA): Suitable for applications requiring high precision and moderate rigidity, like measuring equipment or 3D printers.

- Medium Preload (ZB): The best choice for applications demanding high rigidity and accuracy, such as CNC milling machine axes or machining centers.

- Zero Clearance (Z0): Used where low friction is the priority over maximum rigidity, such as in high-speed transfer units.

Proper lubrication is critical for maximizing the lifespan of any linear guide. Our EG series sliders come pre-lubricated with a high-quality lithium-based grease. We recommend re-lubrication every 100 km of travel or every 6 months, whichever comes first. The sliders feature easily accessible grease nipples for simple maintenance. For high-speed or special environment applications, oil lubrication systems can also be used. Consult the product manual for compatible lubricant types and intervals.

The letters 'H' and 'W' refer to the slider block's geometry.

- EGHCA: This denotes a standard square-type block with flange mounting holes (tapped from the top). It offers high rigidity against moment loads.

- EGWCA: This denotes a wide, low-profile block, also with flange mounting holes. The wider footprint provides increased stability, especially against roll-moment loads (MR).

Absolutely. The four-row circular arc contact design of the High Quality EG Bearing Linear Guides And Linear Slider ensures it has equal load ratings in the radial, reverse-radial, and lateral directions. This means it can be mounted in any orientation—vertical, horizontal, sideways, or upside down—without a significant loss in performance or load capacity, offering maximum design flexibility.

Our commitment to quality is unwavering. All our products are manufactured in an ISO 9001:2015 certified facility. Each linear guide undergoes rigorous quality control, including dimensional checks and running accuracy tests. We provide a standard 12-month warranty against manufacturing defects. Furthermore, our customer support team is available to assist with any technical inquiries, from selection to installation and maintenance, ensuring you get the most out of our products.

We maintain a robust inventory of standard EG series models and rail lengths. For in-stock items, orders are typically dispatched within 24-48 hours. For custom orders, such as non-standard rail lengths or special coatings, the lead time is generally between 1 to 3 weeks, depending on the complexity of the customization. We provide a firm delivery date upon order confirmation to help you manage your project timelines effectively.

Further Reading & Authoritative References

To deepen your expertise, we recommend exploring these authoritative resources. The continuous study of tribology and precision engineering is key to innovation in linear motion.

- Discussion on Linear Guide Precision in DIY CNC Machines: A practical discussion among industry professionals and enthusiasts on achieving high accuracy with components like the EG series. CNCzone Linear Motion Forum

- Scholarly Article on Friction in Linear Guides: A scientific paper delving into the tribological aspects of rolling element linear guides, which forms the basis of our low-friction design. "Friction and wear of linear rolling element bearings under different lubrication conditions" - Tribology International, Volume 119, March 2018.

- ISO Standard for Rolling Bearings: The international standard that defines the calculation methods for dynamic load ratings and rating life, which we use for our product specifications. ISO 281:2007 - Rolling bearings — Dynamic load ratings and rating life