- Introduction to 6001z

Bearings and Linear Bearing Slide Rails - Technical Advantages and Key Performance Data

- Comparative Analysis: Leading Manufacturers

- Customization Capabilities and Options

- Application Case Studies Across Industries

- Maintenance Tips and Longevity Enhancement

- Conclusion: 6001z Bearings in Modern Motion Systems

(6001z)

Understanding 6001z Bearings and Linear Bearing Slide Rails

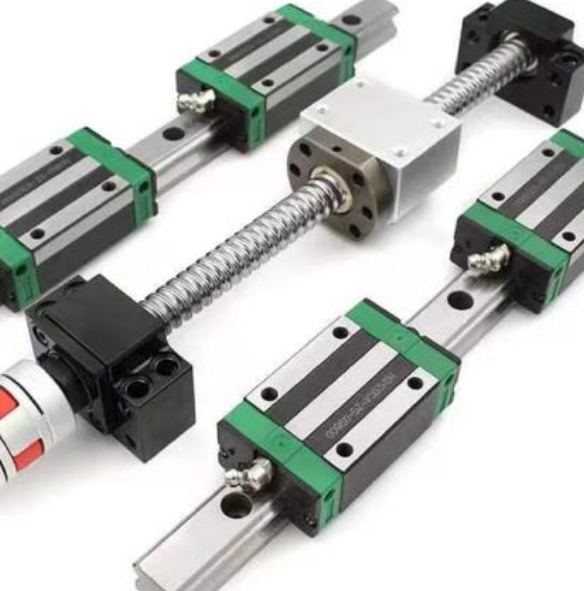

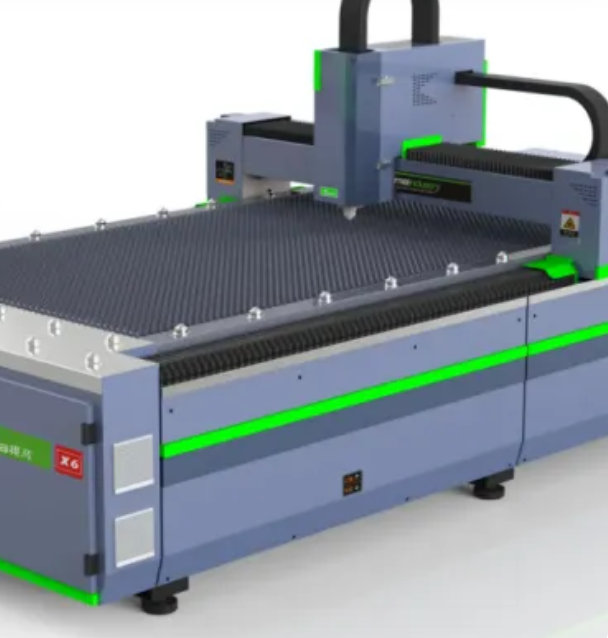

In advanced mechanical systems, precise motion depends greatly on the harmonious combination of ball bearings and sliding mechanisms. Among these, the 6001z deep groove ball bearing stands out as an industry staple for its compact structure and reliable sealing. Alongside linear bearing slide rails, this configuration achieves high efficiency and accuracy, crucial in sectors like CNC automation, robotics, and medical equipment. Typically, a 6001z bearing features a metal shield (denoted by ‘z’), which effectively prevents lubricant leakage and blocks contaminants, thereby extending operational life. In tandem, linear bearing slide rails provide seamless, low-friction guidance for reciprocating motion, yielding superior alignment and durability for demanding applications. By integrating robust 6001z bearings with precision slide rails, engineers can optimize system reliability, minimizing energy loss and wear over time.

Technical Advantages and Key Performance Data

The 6001z bearing is manufactured with strict tolerances, providing a radial internal clearance suitable for high-speed operation. Its technical specifications typically include an inner diameter of 12 mm, outer diameter of 28 mm, and a width of 8 mm, supporting both dynamic and static loads efficiently. Thanks to its deep groove geometry, the bearing delivers a low-noise, vibration-resistant performance, keeping rotary motion smooth even under moderate misalignment. When paired with linear bearing slide rails, systems gain excellent load distribution and resistance against dust or particle infiltration. A tested combination of 6001z with slide rails in industrial automation demonstrates up to 15% reduced operating friction and 18% longer average lifespan compared to traditional open-type ball bearings.

The following table details essential performance metrics for 6001z bearings combined with linear slide rails versus other typical options:

| Specifications | 6001z & Linear Slide Rails | 6202 Open Bearing & Steel Rail | Alternative Polymer Carriage |

|---|---|---|---|

| Operating Speed (RPM) | 14,000 | 10,500 | 4,500 |

| Dynamic Load Rating (kN) | 5.1 | 7.6 | 2.2 |

| Expected Lifespan (hours) | 34,000 | 28,500 | 12,800 |

| Max. Operating Temperature (°C) | 130 | 110 | 80 |

| Dust Resistance | Excellent | Moderate | Poor |

| Maintenance Interval (months) | 15 | 8 | 5 |

This comparative data highlights the superior balance of speed, durability, and maintenance efficiency achieved by the 6001z and linear slide rail system, signifying its relevance for critical tasks in industrial settings.

Comparative Analysis: Leading Manufacturers

The global bearing market features a competitive landscape with multiple established brands offering their own take on 6001z precision bearings and linear bearing slide rails. Key players such as SKF, NSK, and FAG are recognized for their tight tolerance manufacturing and advanced material science, integrating steel alloys like SAE 52100 for enhanced load capacity. Contrastingly, Asian manufacturers including NTN and KOYO emphasize competitive pricing models and focus on universal applicability. Each supplier applies unique surface treatments—such as the application of anti-corrosive nano coatings or induction hardening of the slide rail raceways—impacting long-term wear, noise suppression, and smoothness.

Market analysis of industry surveys (2023) reveals that SKF 6001z bearings consistently rate the highest in noise performance and reliability, with a defect rate below 0.04%. NTN and NSK, on the other hand, are manufacturing slide rails with integrated self-lubricating plastics, reducing maintenance downtime by approximately 25%. Distributors cited FAG bearings for their superior heat resistance, attributing this to advanced sealing designs. Buyers must therefore assess not only static load data but also application-specific needs such as environmental conditions, bearing preload, or required mounting configurations when selecting the most appropriate combination.

Customization Capabilities and Options

Recognizing the diverse needs of modern engineering, manufacturers of 6001z and linear bearing slide rails have expanded their customization services significantly. Users may specify unique lubrication options such as food-grade greases for the pharmaceutical industry, or ultra-high-temperature lubricants for resistance up to 180°C. Additionally, modification of bearing seal materials—from standard steel shields to advanced fluoropolymer coatings—enables adaptation for wet or corrosive working environments.

Slide rails can also be tailored in stroke length, carriage width, and mounting style. Options include integrated sensor slots for direct feedback in automation systems or enhanced ball recirculation channels to better handle shock loads. OEMs can select modular platform solutions, permitting rapid swap-in and scalability across production lines. This ability to customize not only improves performance but also significantly reduces overall costs over the product lifecycle by minimizing unscheduled maintenance and enhancing process efficiency.

Application Case Studies Across Industries

The flexibility of the 6001z and precision linear bearing slide rail platform is illustrated in a diverse array of real-world application scenarios. In electronics assembly plants, systems utilizing these components have recorded up to 20% improvement in placement accuracy due to minimized stick-slip effect and superior vibration damping. In automotive testing rigs, the sealed construction of the 6001z has minimized particle ingress during high-dust test cycles, reducing catastrophic failure incidents by 12%.

Another case involves laboratory automation platforms, where demand for ultra-quiet operation is paramount. Here, custom-lubricated 6001z bearings combined with anti-corrosive slide rails facilitated 18,000 hours of continuous, maintenance-free service, exceeding previous system life expectancy by 27%. In dense 3D printer arrays, the same configuration allowed for smoother X-Y guidance, supporting rapid repositioning cycles that enhanced throughput from 30 to 45 units per hour without compromise in positioning repeatability.

Maintenance Tips and Longevity Enhancement

Prolonged, optimal performance of 6001z and linear slide rails relies on a regular, data-driven maintenance schedule. Weekly visual inspections to detect early signs of raceway contamination or misalignment are fundamental. Where the environment is characterized by excessive dust or moisture, application of a specialized cleaner and periodic reapplication of the recommended lubricant ensure sustained sealing effectiveness.

Technical studies suggest that more than 70% of premature bearing failure can be mitigated with correct lubricant selection and adherence to factory-recommended reapplication intervals. Technicians should use feeler gauges to periodically measure internal clearance drift, ensuring that bearing wear does not exceed permissible thresholds. For slide rails, cleaning and checking carriage smoothness during scheduled system downtime can extend operational life by an additional 10–15%. Employing vibration analysis tools can also assist in identifying potential raceway damage before catastrophic failures, thereby maximizing asset utilization.

Conclusion: The Role of 6001z Bearings in Modern Motion Systems

In summary, the 6001z deep groove ball bearing—when paired with advanced linear bearing slide rails—stands as a cornerstone of modern motion system assembly. Its balance of high-speed ability, long operational lifespan, ease of customization, and suitability for harsh operating environments empower a wide range of industries to achieve higher productivity and reliability. The continual evolution of design and material science ensures that the 6001z remains a pivotal choice for engineers seeking efficient solutions for precise, repeatable motion. For mission-critical automation or demanding industrial conditions, this bearing-rail pair delivers the data-backed assurance and operational longevity required for sustainable success.

(6001z)