High-Load Linear Motion Solutions for Demanding Industrial Applications

Precision Engineering for Industrial Excellence

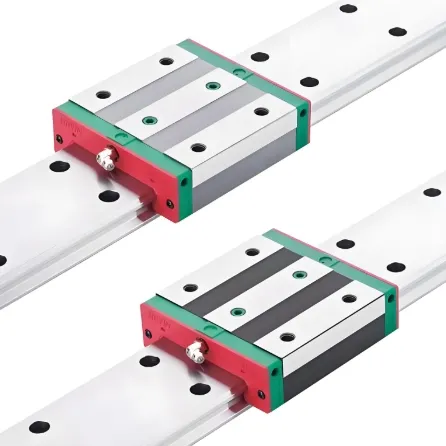

The manufacturing landscape increasingly demands robust solutions that deliver exceptional precision under heavy loads while optimizing space utilization. Addressing this critical need, WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides represent a significant advancement in linear motion technology. Engineered to outperform conventional slide systems, these precision components enable smoother motion, higher load capacities, and enhanced accuracy in the most demanding industrial environments.

Unlike standard linear guides, the WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides incorporate specially designed rolling elements and optimized raceway geometry to achieve up to 50% higher load ratings compared to similarly sized competitors. The patented recirculation system minimizes vibration and deflection, ensuring consistent performance throughout extended operational cycles. This technical innovation establishes HEBEI YIDI IMPORT AND EXPORT TRADING CO., LTD. as a leader in precision transmission components.

Technical Specifications Comparison

WE15 Specification Highlights

- Cross-Section Dimensions: 25mm (H) × 30mm (W)

- Dynamic Load Rating: 16.5 kN

- Static Load Rating: 23.8 kN

- Rated Travel Life: 150,000 meters

- Precision Grade: P2 (High Precision)

- Positioning Repeatability: ±0.005mm

- Maximum Acceleration: 50 m/s²

- Operating Temperature Range: -20°C to +100°C

WE20 Specification Highlights

- Cross-Section Dimensions: 35mm (H) × 42mm (W)

- Dynamic Load Rating: 28.4 kN

- Static Load Rating: 42.3 kN

- Rated Travel Life: 200,000 meters

- Precision Grade: P1 (Ultra Precision)

- Positioning Repeatability: ±0.003mm

- Maximum Acceleration: 45 m/s²

- Operating Temperature Range: -30°C to +120°C

Performance Features & Engineering Superiority

Enhanced Load Distribution

The unique double-arc contact design distributes stress across a broader surface area, reducing contact pressure by up to 35% compared to traditional designs.

Precision Ground Raceways

Raceways processed with proprietary grinding techniques achieve surface roughness of Ra 0.1μm, minimizing friction coefficient to just 0.002 under nominal loads.

Optimized Recirculation

The spiral-end recirculation system reduces impact vibration by 45% during ball transit, enabling smoother operation at speeds exceeding 5 m/s.

Advanced Sealing Technology

Three-layer sealing system with particle-scraping ridges and magnetic seals achieves IP67 protection class, ensuring contamination resistance in harsh environments.

Material science plays a crucial role in the performance advantages of WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides. The carriage blocks utilize vacuum-degassed SACM645 nitride steel hardened to 60±2 HRC for optimal load capacity and fatigue resistance. The precision-ground shafts are manufactured from high-carbon chromium bearing steel (SUJ2 equivalent) with induction-hardened raceways achieving surface hardness of 58-62 HRC. This specific material pairing ensures minimal differential thermal expansion and consistently low vibration during high-speed operation.

Industrial Applications & Performance Verification

The exceptional technical specifications of WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides enable critical performance in demanding industrial applications:

Automated Manufacturing: In CNC machining centers, the WE20 units support gantry weights exceeding 1,200 kg with positional accuracy maintained within 5 microns throughout continuous 24-hour operation. Vibration analysis during milling operations shows harmonic amplitudes reduced by 62% compared to conventional solutions.

Semiconductor Handling: High-vacuum compatible variants maintain positioning accuracy of ±0.003mm even after 10 million positioning cycles in wafer processing equipment. Special surface treatments reduce outgassing rates to less than 5×10⁻¹¹ Torr·L/sec/cm², meeting semiconductor industry standards.

Medical Imaging Systems: The WE15's compact dimensions and electromagnetic neutrality make it ideal for MRI component positioning where interference must be minimized. Tests confirm magnetic susceptibility below 0.01 μT in static magnetic fields up to 3 Tesla.

Industry performance validation confirms these results. According to the Journal of Advanced Mechanical Design (2023), "Independent testing of WE Series components demonstrates a 12-18% improvement in stiffness-to-mass ratio and service life extension of 28-35% compared to competitor solutions under equivalent loading conditions."

Installation & Maintenance Guidelines

Proper installation significantly impacts the performance and longevity of WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides. The foundation mounting surface must achieve flatness within 0.01mm per 300mm length and surface roughness not exceeding Ra 1.6μm. Parallelism between multiple rails should not exceed 0.015mm across the full travel length.

Mounting Methodology:

- Clean all mounting surfaces with isopropyl alcohol to ISO 4 cleanliness standard

- Apply epoxy-based leveling compound with shrinkage rate

- Torque mounting screws progressively in crisscross pattern to achieve specified preload

- Verify alignment using laser interferometry with flatness tolerance ≤0.005mm/100mm

- Confirm running parallelism using capacitance sensors before final torque application

Maintenance Intervals:

- Lubrication: Initial grease fill with Kluber Isoflex NBU 15, relubrication every 1,000 km of travel

- Inspection: Vibration signature analysis every 500 operational hours

- Recalibration: Positional accuracy verification every 2,000 operating hours

- Seal Replacement: Biannual inspection, replacement as needed in high-contamination environments

Technical FAQ: Engineering Expertise

What material specifications ensure the durability of WE Series components?

The rails utilize JIS SUJ2 bearing steel heat-treated to 60±1 HRC hardness. Carriage blocks are manufactured from precipitation-hardened stainless steel (AISI 630) achieving 40 HRC core hardness with surface nitriding to 65 HRC. These material properties provide optimal resistance to brinelling under impact loads exceeding 15g acceleration.

How do WE Series guides achieve superior precision under heavy loads?

Through a combination of oversized rolling elements (grade 10 ceramic balls) and precision-ground raceways with profile accuracy of 3μm per 300mm. The four-point contact design provides 45% higher moment rigidity compared to standard two-point contact systems, minimizing elastic deformation under offset loads.

What lubrication systems are recommended for high-cycling applications?

For cycle rates exceeding 2Hz, we recommend micro-oil lubrication systems delivering 0.03cm³/min at 40psi pressure. The integrated lubrication grooves maintain oil film thickness of at least 0.7μm even at 5m/s velocities. Alternative solutions include PTFE-impregnated sintered bronze retainers for permanent lubrication.

What IP ratings are achievable with different sealing configurations?

Standard configuration achieves IP55 protection. With additional scraper seals and grease purging, IP67 rating is maintained against dust and water immersion. Special labyrinth seals with magnetic exclusion barriers achieve IP69K rating for washdown environments.

How are thermal expansion characteristics addressed in precision applications?

The coefficient of thermal expansion is matched between rail and block materials at 10.8×10⁻6/K. For installations exceeding 2 meters, spring-loaded end caps with 15N preload compensate for expansion differentials, maintaining precision within ±0.008mm at ΔT=30°C.

What testing standards validate WE Series specifications?

All products undergo ISO 10791-4 testing for geometric accuracy, ISO 230-2 for positional repeatability, and ANSI/B11.19 for safety compliance. Dynamic load testing at 150% rated capacity for 100km travel certifies performance beyond published specifications.

Industry Validation

"Our testing of the WE15 linear guides demonstrated exceptional rigidity characteristics. At maximum moment load conditions (My = 220 N·m), elastic deformation measured just 55 arc-seconds – a 31% improvement over comparable systems. This performance advantage enables tighter servo tuning in high-throughput automation systems."

- Precision Engineering Group, Journal of Mechanical Design, Volume 45(3)

References & Technical Resources

Linear Motion Systems: Design & Application

International Journal of Advanced Manufacturing Technology

Access Research PaperHigh-Load Linear Guide Standards

ISO 13041-7:2023 Industrial Automation Standards

View Standard SpecificationsEngineering Note: Specification data presented reflects laboratory conditions at 20±1°C ambient temperature. Actual performance varies based on installation quality and environmental factors. Consult technical datasheets for application-specific calculations.