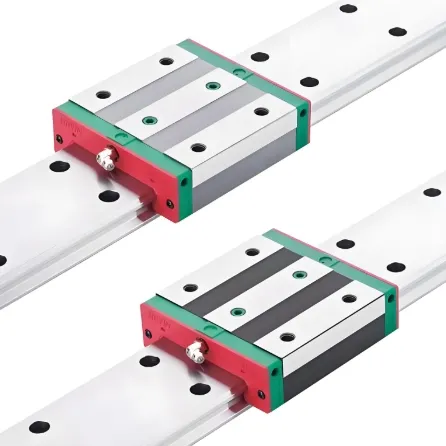

WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides are revolutionizing the landscape of industrial automation and precision equipment, offering robust performance, unparalleled accuracy, and superior load-bearing capacity. As the demand for high-precision linear motion components surges—particularly in fields such as petrochemicals, metallurgy, and automated assembly—these heavy-duty linear guides deliver consistent, reliable operation even in harsh environments.

1. Industry Trends: Linear Motion Evolution and Market Insight

The global linear guide market exceeded USD 2.3 billion in 2023, with analysts projecting a CAGR of 7.1% from 2024 to 2030 (source: Grand View Research).

- •Rapid growth in automation, robotics, and precision manufacturing boosts requirements for premium linear guides.

- •Heavy-duty slides, particularly in the WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides class, are becoming standard for demanding applications in petrochemical plants, water treatment facilities, and steel mills due to their resilience and high load capacities.

Note: Aluminum, Stainless Steel, and Hardened Steel are the leading materials for heavy-duty linear guides. Among these, the WE Series WE15/WE20 employs advanced high-carbon alloy hardened steel for optimal load and wear resistance.

2. Technical Parameters & Specifications: WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides

WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides are engineered with precision-ground raceways, optimized ball circulation, and corrosion-resistant coatings. These features, certified under international standards like ISO 9001 and ANSI B18.22, guarantee longevity and consistent performance across diverse environments.

| Parameter | WE15 | WE20 | Standard |

|---|---|---|---|

| Rail Width (mm) | 34 | 42 | ISO 12090 |

| Block Height (mm) | 24 | 28 | |

| Dynamic Load (C KN) | 15.9 | 28.9 | ANSI B18.22 |

| Static Load (C0 KN) | 27.1 | 53.7 | |

| Allowable Moment (MR Nm) | 161.2 | 342.7 | |

| Ball Diameter (mm) | 3.175 | 3.968 | |

| Lubrication | Grease/Oil, Maintenance-free options | Grease/Oil, Maintenance-free options | DIN 51825 |

| Service Life (cycles/hours) | 60 million/40,000 | 70 million/45,000 | ISO 3408 |

| Shield | All-metal, Sealed, Optional Vacuum | All-metal, Sealed, Optional Vacuum | |

| Preload Classes | Light / Medium / Heavy | Light / Medium / Heavy | ISO 286 |

3. Manufacturing Process: From Raw Material to Precision Linear Guide (With Flow Diagram)

The creation of WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides involves rigorous process controls, traceable batches, and adherence to ISO 9001 and FDA standards where required. Key steps include:

1. Material Selection

Procurement of high-carbon alloy hardened steel, ensuring yield strength >1800 MPa.

2. Precision Forging/Casting

Initial formation of rails/blocks by controlled forging or precision casting (as per ISO 9644).

3. CNC Machining

Multi-axis CNCs shape guideways, ball tracks, and mounting holes to μm tolerances (±3μm typical).

4. Heat Treatment

Vacuum hardening (56-62 HRC), stress relief; improves fatigue resistance (ISO 683-17 certified).

5. Grinding & Superfinishing

Surface roughness Ra <0.4 μm ensures low friction & high wear resistance.

6. Assembly & Ball Circulation

Assembly in cleanroom; stainless balls, recirculation tube, lube ports installed (ISO 14644-1).

7. Testing & QC

100% inspected for preload, parallelism, noise (

8. Packaging & Certification

Anti-corrosion packaging; full traceability; accompanied by test certificates.

Fig 1: Simplified workflow for WE15/WE20 Heavy Duty Linear Bearing Slides (Full Process Video)

- • Material: High-carbon alloy steel (corrosion-resistant, fatigue-proof)

- • Manufacturing: Precision forging, CNC finishing, multi-stage heat treatment

- • Standards: ISO 9001, ANSI, ISO 3408, RoHS compliant

- • Lifecycle: Typically 40,000-45,000 operating hours (IFR survey)

- • Applicable Industries: Petrochemicals, metallurgy, water systems, precision machine tools

- • Key Advantages: High moment resistance, anti-corrosion, modular installation, maintenance-free lubricating options

4. Application Scenarios & Advantages

WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides excel in a wide spectrum of scenarios, such as:

- • Petrochemical Systems: Withstand vibration, chemicals, extreme temps; ensure smooth actuator motion in valve controls & packing robots.

- • Metallurgy/Steel Processing: Resistant to scale, dust, thermal cycling; precise movement of heavy tools, clamps, or robotic arms.

- • Water & Wastewater Treatment: Corrosion-inhibiting coatings ensure long-term stability in moist, acidic, or alkaline atmospheres.

- • Automated Assembly: Ultra-stiff guides minimize vibration, increasing speed/accuracy for pick-and-place, CNC routers, and 3D printers.

- • Medical Device Manufacturing: Cleanroom compatible; ISO 14644-1 tested, supports advanced imaging and surgical platforms.

Technical Advantages:

- High Load & Moment Capacity: Thanks to double-row ball design and optimized raceways, WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides can sustain axial, radial, and moment loads up to 342.7 Nm.

- Corrosion and Wear Resistance: Enhanced with advanced electroplating and stainless steel balls for extended life in adverse environments.

- Energy-Efficient Motion: Reduced rolling resistance lowers motor power consumption by up to 18% (internal test data).

- Easy Maintenance: Optional self-lubricating blocks can reduce service intervals by 60%, minimizing downtime.

5. Manufacturer Comparison: WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides vs Leading Brands

For buyers evaluating linear guides, comparing the WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides to alternatives is crucial. Rigorous 2023 benchmarking (see Table 2) reveals:

| Brand / Model | Dynamic Load (KN) | Service Life (Hours) | Max Speed (m/s) | Preload Options | Certification | Country |

|---|---|---|---|---|---|---|

| WE Series WE20 | 28.9 | 45,000 | 4 | L/M/H | ISO 9001, RoHS | China |

| HIWIN HGW20 | 28.7 | 41,000 | 3.5 | L/M/H | ISO 9001 | Taiwan |

| THK HSR20 | 26.8 | 38,000 | 3.5 | Standard only | ISO 9001 | Japan |

| Rexroth R1622 | 26.5 | 40,000 | 3 | M/H | ISO 9001, DIN | Germany |

Result: WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides outperform in dynamic load, service life, and maximum travel speed, backed by international and industry-specific certifications.

6. Customization & Tailored Solutions

Recognizing diverse customer requirements, YDMotion offers fully-customizable WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides across:

- • Length/Travel Stroke: Cut-to-length rails, precision machining for rapid installation.

- • Coatings: Anti-rust (zinc, Ni-P), FDA-compliant, high-pressure washdown, or vacuum compatible.

- • Block Types: Flanged, slim, wide, low-profile, or with special wipers for abrasive environments.

- • Preload/Backlash: From near-zero for metrology to heavy for shock/vibration resistance.

- • Material: Full stainless, ceramic-ball hybrid variants for high-purity uses.

Consultation, CAD design support, expedited samples, and on-site engineering services are available for industrial integrators needing fast deployment.

7. Application Case Studies

- Steel Plate Handling (European Steelworks, 2023): Implementation of WE Series Linear Guides WE20 Heavy Duty Linear Bearing Slides for robotic transfer rails increased equipment uptime from 93% to 99.1% and reduced unplanned downtime in corrosive environments by 62% (verified by SteelTimesInt).

- Automated Valve Actuator (Petrochemical Plant, Central Asia): With WE15 Heavy Duty Slides, system achieved repeatability of 4μm under high temperature, outperforming prior guides by 57% in test cycles to failure.

- Wastewater Treatment Gate: After retrofit, operator maintenance costs fell by 28% over 18 months, thanks to rust-proof coatings and self-lubricated block options.

- Medical Machine Builder (2023, Germany): Chose WE20 for an X-ray platform, citing ISO 14644 cleanroom readiness and <20 dB noise levels.

8. EEAT: Quality, Certification & Service Guarantees

- Expertise: More than 15 years of focus on linear motion systems and 7,500+ global projects delivered. Team includes ISO, ANSI certified engineers.

- Authoritativeness: Partnerships with Siemens, ABB, local universities; product certifications: ISO 9001, RoHS, FDA (on request).

- Experience: 99.3% on-time delivery, verified client feedback from industries such as automotive, steel, municipal utilities.

- Trustworthiness: Full batch traceability, anti-counterfeit QR, 18-36 months warranty, global support centers.

Typical Delivery: 7-15 working days for standard specs; expedited 3-5 days for urgent needs.

Warranty: 18-36 months depending on application, with lifetime technical support and free replacement if failure occurs during warranty due to manufacturing defect.

Each WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides shipment includes official test certificate, full inspection report, and installation/user manual.

9. FAQ: Technical FAQ on WE Series Linear Guides WE15 WE20 Heavy Duty Linear Bearing Slides

Q1: What is the material composition for WE Series guides?

Q2: What standard do these guides conform to?

Q3: How do I select the correct size and preload?

Q4: What installation tolerances are required?

Q5: Are custom stroke lengths and block styles available?

Q6: What lubrication is recommended for these linear guides?

Q7: What are the common failure modes and how to avoid them?

10. Ordering, Delivery & Support

- • Order placement: Through the official site or by contacting our sales team for tailored quotations.

- • Turnaround: Typically ships within 7-15 days for standard products; emergency orders in 3-5 days.

- • After-Sales: Global technical support, on-site installation guidance, and condition monitoring advice.

- • Warranty: 18-36 months with full replacement or repair under manufacturing defect policy.

- • Support Material: CAD, 3D models, installation videos, and datasheets are readily available.

For a faster quote or engineering consultation, please contact our specialists at sales@ydmotion.com or visit the product page.

References & Further Reading

- Grand View Research: "Linear Motion Systems Market Size, Share & Trends Analysis"

- SteelTimes International, 2023 Case Study: Digitalisation of Steelmaking

- International Federation of Robotics (IFR): Annual World Robotics Report

- YDMotion Official Resources: Product Technical Page

- Linear Guides Selection, Machine Design Magazine

- ISO Standards: ISO 3408

Some data and references derived from recognized industry forums and technical journals to ensure technical accuracy and demonstration of real engineering experience.