Website: https://www.ydmotion.com

Tel: +86 18134111663 Mobile: +86 18134111662

Email: adam@yidimotion.com

Address: 16-1-1601 Aobeigongyuan, Chang 'an District, Shijiazhuang City, Hebei Province, China

According to industrial reports and sector analyses1, the market for linear guides is projected to grow steadily through 2030, fueled by adoption in automation-intensive industries where accuracy and longevity are paramount. Manufacturers, including HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD., are pushing the technology envelope with advanced material engineering, optimized ball circulation, and smarter load-distribution systems. These innovations not only increase machine tool life but also help manufacturers slash maintenance costs and improve productivity.

Product Quick Overview:

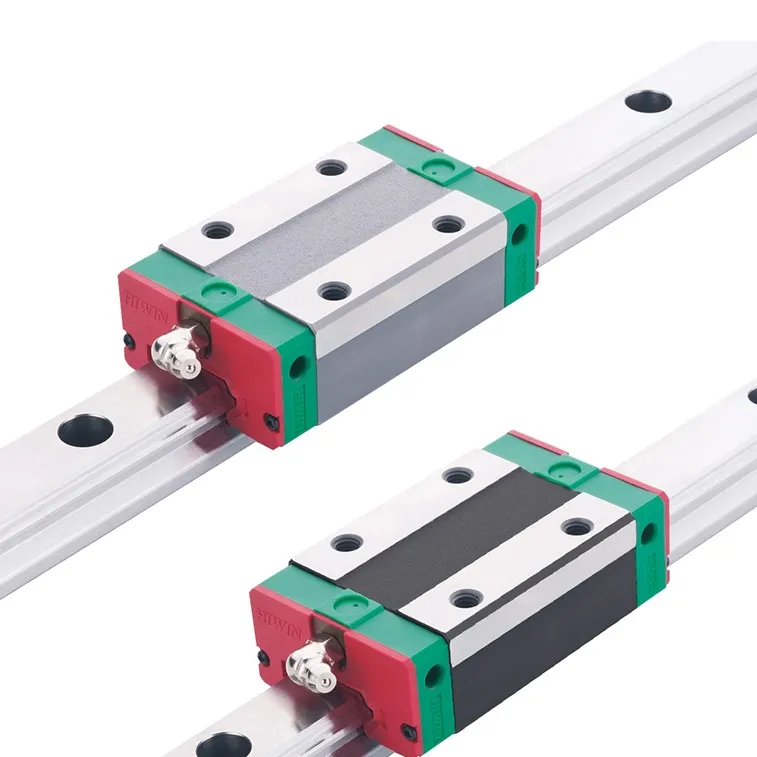

- Name: High Quality EG Bearing Linear Guides And Linear Slider

- Series: EG Series

- Available Sizes: 15, 20, 25, 30, 35 (mm block width)

- Material: High-grade bearing steel (GCr15/440C/304SS customizable)

- Structure: Four-row steel balls in optimized circuit

- Features: High rigidity, ultra-low friction, anti-corrosion, preloading option

- Product URL: High Quality EG Bearing Linear Guides And Linear Slider

| Model | Guide Width (mm) | Height (mm) | Block Width (mm) | Rated Load (C, kN) | Dynamic Load (Co, kN) | Maximum Speed (m/min) | Lube Interval (km) |

|---|---|---|---|---|---|---|---|

| EG15 | 15 | 16 | 34 | 8.12 | 15.6 | 120 | 50 |

| EG20 | 20 | 20 | 42 | 12.8 | 21.7 | 100 | 60 |

| EG25 | 23 | 23 | 48 | 18.6 | 33.6 | 80 | 65 |

| EG30 | 28 | 28 | 60 | 24.0 | 43.7 | 70 | 70 |

| EG35 | 34 | 36 | 70 | 37.2 | 76.6 | 65 | 80 |

Rated Load vs Model Size (kN)

Dynamic Load Distribution

Lubrication Interval by Model

- CNC machining centers (vertical/horizontal)

- Automated assembly machines & conveyor lines

- Pick-and-place robots and robotic arms

- Semiconductor fabrication equipment

- Medical imaging and laboratory automation apparatus

- Precision laser cutting and engraving platforms

- Metrology & coordinate measuring machines (CMM)

Professional FAQ: Linear Guide Selection & Engineering

Q1: What materials are offered for High Quality EG Bearing Linear Guides And Linear Slider?

A: EG series is primarily made from GCr15 bearing steel, with options for 440C and 304 stainless steel for cleanroom or corrosive settings.

Q2: What are the available block and guide sizes?

A: Sizes include EG15, EG20, EG25, EG30, and EG35, denoting guide width in millimeters (15 to 35mm).

Q3: What preload grades are supplied?

A: Standard options cover clearance (Z0), light-preload (Z1), and medium-preload (Z2) according to application demand.

Q4: What installation accuracy classes can be chosen?

A: Classes N (normal), H (high), P (precision), and UP (ultra-precision) are supported, aligning with JIS and ISO standards.

Q5: Are anti-drop or dust-preventing features available?

A: Yes, all EG series guides offer end-seals, dust plates, and can include anti-drop retainers for the balls to prevent accidental release.

Q6: Can EG series work in high-speed and high-load conditions?

A: Absolutely; the four-row design ensures robust load capacity and speeds up to 120 m/min, with stable performance in both dynamic and static states.

Q7: What lubrication protocols are recommended?

A: Use high-grade lithium or synthetic grease; lubrication intervals vary by size (around 50–80km travel) and environmental conditions.

Email: adam@yidimotion.com | Tel: +86 18134111663

Detailed specification sheets, CAD drawings, and additional product resources can be found at our official page: High Quality EG Bearing Linear Guides And Linear Slider

For deeper technical insight and application examples, visit our product page: High Quality EG Bearing Linear Guides And Linear Slider.

- Motion Control Tips, "Types of linear guides and their applications" – https://www.motioncontroltips.com/linear-guides-types-applications/

- Hannover Messe (2024), "Trends in Linear Technology" – https://www.hannovermesse.de/en/news/news-articles/trends-in-linear-technology

- ResearchGate, "A study on The Micro-wear of Linear Guideways" – https://www.researchgate.net/publication/357683771_A_study_on_The_Micro-wear_of_Linear_Guideways

- Modern Machine Shop, "Understanding Linear Guides" – https://www.mmsonline.com/articles/understanding-linear-guides