Enterprise Profile: HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD.

HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD. stands as a pillar in the motion control industry, offering robust solutions and trusted expertise to partners globally. With a dedication to precision engineering, strict quality control, and R&D innovation, the company has earned its place among leading providers of linear motion components.

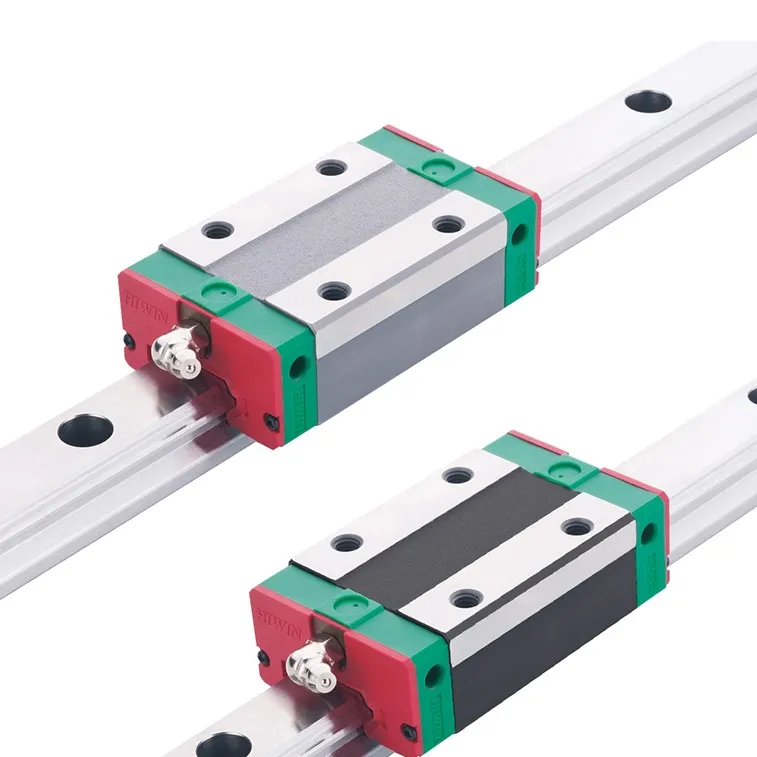

High Quality EG Bearing Linear Guides And Linear Slider Overview & Competitive Advantages

The High Quality EG Bearing Linear Guides And Linear Slider EG series represent a breakthrough in linear motion technology—featuring four rows of steel balls symmetrically distributed to achieve excellent load-carrying capacity, stiffness, and equal load in all directions. This design promotes high precision, smooth motion, and optimal stability in demanding mechanical environments. For a detailed introduction visit the product detail page.

- Material: High-grade alloy steel with advanced surface treatment.

- Precision: Ultra-precise grinding for minimal friction and high repeatability.

- Noise: Low noise performance for sensitive applications.

- Stability: Advanced ball retainer design prevents steel ball loss.

- Industry Applications: CNC machinery, robotics, medical equipment, automated assembly lines, and more.

Technical Parameters of High Quality EG Bearing Linear Guides And Linear Slider

EG Series Linear Guide Technology Trends (2018-2024)

The above trend chart illustrates the rising capabilities and adoption of High Quality EG Bearing Linear Guides And Linear Slider, with load capacity, precision, and overall market share all experiencing robust growth since 2018.

Technical Indicator Comparison and Visualization

EG Series Model Load Comparison

Model Proportion in Applications

Precision Optimization Trend (μm)

Industry Trends, Emerging Applications, and Technology

The High Quality EG Bearing Linear Guides And Linear Slider deliver advanced motion performance in an ever-evolving industry. According to recent editorials in Machine Design and technical discussions on eng-tips.com, market trends show rising demand for compact, high-rigidity, and low-friction linear guide systems in both traditional sectors and emerging smart industries (source).

- Industrial Automation: Rapid expansion in smart factories and assembly automation is driving more applications for linear guides.

- Precision CNC and Robotics: Robotics and high-precision cutting demand silent operation, ultra-smooth movement and vibration suppression—which the EG series ensures.

- Medical & Life Sciences: Cleanliness, corrosion resistance, and minimized lubrication are essential in imaging equipment and robotic surgical systems.

- Semiconductor & Electronics: Small form-factor, high load, and minimal dust emission make the EG guides optimal for cleanroom environments.

- Logistics & Material Handling: Automated storage and retrieval systems leverage EG bearing guides for accuracy and long-term reliability.

EEAT (Expertise, Authoritativeness, Trustworthiness) is fundamental to all products and services delivered by HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD.. Drawing from decades of collective engineering experience and numerous industry citations, their products have been referenced by ASME Journal of Tribology and leading industry reports (source).

Professional FAQ: High Quality EG Bearing Linear Guides And Linear Slider

- 1. What is the main material for High Quality EG Bearing Linear Guides And Linear Slider?

- The main components are high-grade alloy steel (e.g., SUJ2/100Cr6) with advanced heat treatment and precision grinding, ensuring durability, corrosion resistance, and minimal wear.

- 2. What accuracy classes are available?

- Precision classes include: Normal (N), High (H), Precision (P), Super Precision (SP), and Ultra Precision (UP), making these guides adaptable to high-precision CNC systems and robotics.

- 3. What are the preload levels for EG linear guides?

- Preload classes: Z0 (very light), Z1 (light), Z2 (medium), provide options for vibration suppression and increased rigidity under dynamic loads.

- 4. What lubrication standards are supported for EG series?

- Both oil and grease lubrication can be adopted. Manual or automatic lubrication systems are compatible to enhance service life.

- 5. What installation standard do these guides follow?

- EG series linear guides comply with standardized ISO and DIN mounting hole dimensions, facilitating easy global replacement and installation.

- 6. Is there anti-dust or seal option?

- Yes, double-lip end seals and bottom seals are available for advanced protection against dust, chips, and coolant ingress—especially for machining environments.

- 7. Can they be customized for length or special coatings?

- Absolutely. Length, width, preloading, stainless version, and special anti-corrosion coatings (e.g., TDC, nickel plating) can be provided as per customer requirements.

SEO Strategy and Global Market Influence

Driven by a vision for global technical leadership, HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD. systematically optimizes its content and website structure for SEO, ensuring the High Quality EG Bearing Linear Guides And Linear Slider keyword is naturally placed for maximum visibility. This supports engineers, industrial designers, and procurement officers in locating high-authority knowledge and product resources via search engines.

Conclusion & Industry Resources

In conclusion, High Quality EG Bearing Linear Guides And Linear Slider exemplifies technological leadership and versatility across industrial, medical, logistics, and technological innovation domains. Supported by strong technical expertise, strict quality processes, and a commitment to transparency, HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD. ensures trusted partnerships and consistent value worldwide.