Website: https://www.ydmotion.com

Tel: +86 18134111663 Mobile: +86 18134111662

E-mail: adam@yidimotion.com

Address: 16-1-1601 Aobeigongyuan, Chang 'an District, Shijiazhuang City, Hebei Province,China

Industry Trends: The Growing Demand for bearing linear guide Solutions

The precision motion control industry is evolving rapidly, with bearing linear guide technologies at the forefront of automation, robotics, CNC machinery, 3D printing, and semiconductor manufacturing. Robust, precise, and low-maintenance solutions like the bearing linear rail and heavy duty linear bearing slides are in high global demand for applications ranging from high-speed production lines to ultra-precision laboratories.

As manufacturing shifts towards smart, digitalized systems, requirements for outstanding positioning accuracy, load capacity, and modularity in bearing linear slide rails have surged. Reports from the Motion Control Online Forum and the Precision Engineering Journal indicate a 6.5% CAGR in the global linear guide market from 2021 to 2027 (source).

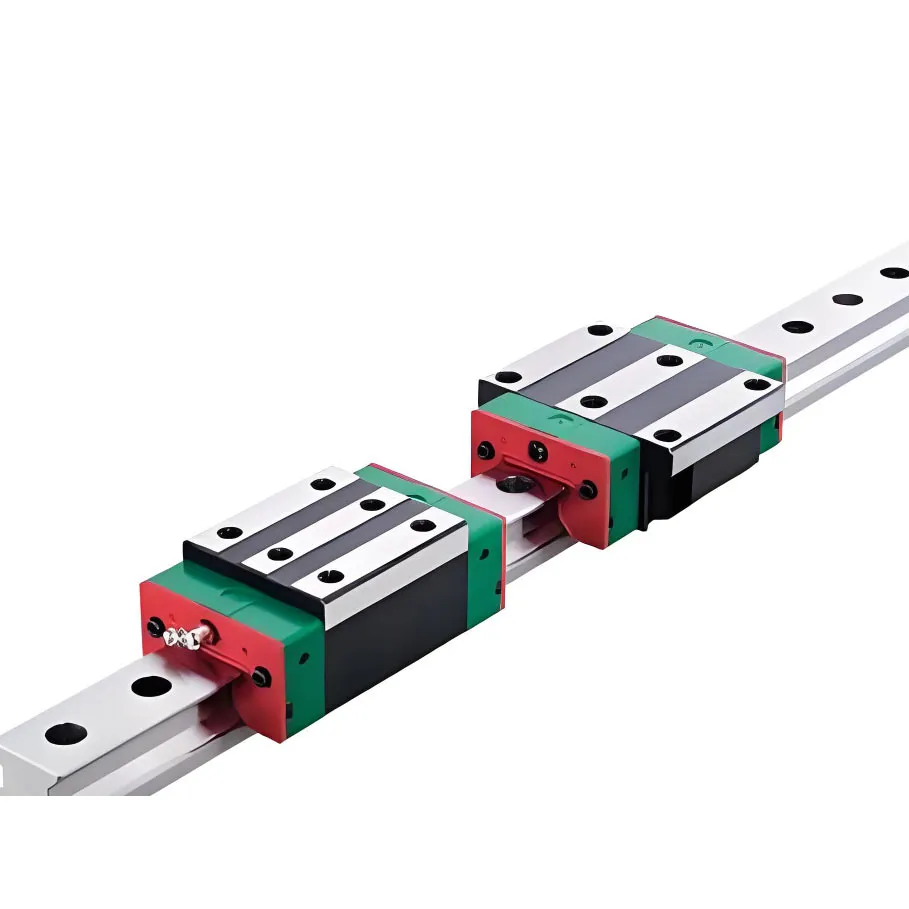

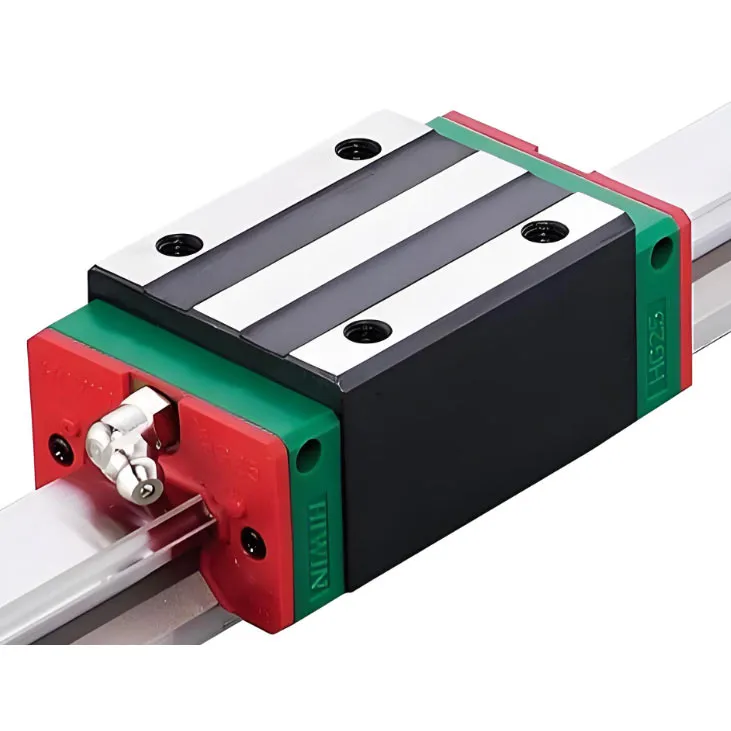

Introducing Heavy Duty Linear Bearing Slide Rails RGH65

The bearing linear guide RGH65 is designed as the heart of precision linear motion systems.

Product Details:

A linear guide (or linear guideway) contains a guide rail, slider (carriage), arrayed balls/rollers, and efficient sealing. It delivers micron-level repeat positioning through rolling-contact, ensuring minimal friction, smooth movement, and outstanding rigidity. Its multi-slider layout handles radial, anti-radial, and lateral loads — essential for demanding industrial and automation applications.

Choose models according to load, speed, accuracy (C-level / P-level), and operating environment (dust-proof, anti-corrosive). YIDI provides personalized selection and technical support to meet your project needs.

Explore product details: Heavy Duty Linear Bearing Slide Rails RGH65

Technical Parameter Table: bearing linear guide Core Specifications

| Model | Rail Width (mm) | Slider Length (mm) | Load Capacity (kN) | Accuracy Grade | Maximum Speed (m/s) | Friction Coefficient | Environment Option |

|---|---|---|---|---|---|---|---|

| RGH65 | 65 | 220-380 | 165 | C/P | 5 | 0.002~0.003 | Dustproof/Anti-corrosive |

| HGH20 | 20 | 86 | 15.7 | C/P | 4 | 0.003 | Standard |

| MGN12 | 12 | 60 | 5.1 | C/P | 2.5 | 0.0027 | Corrosion-resistant |

| EG30 | 30 | 130 | 42 | C/P | 3 | 0.0029 | Dustproof |

| HRR45 | 45 | 160 | 80 | C/P | 4.8 | 0.0028 | High Temperature |

Heavy Duty Linear Bearing Slide Rails RGH65 — Technical Index Visualization

Main Applications of Bearing Linear Guide Systems

- Industrial Automation: Robots, manipulator arms, assembly lines requiring high repeatability.

- CNC Machining Centers: High-load machine tools, heavy duty cutting, and profile machining.

- 3D Printing: Ensuring stable, smooth movement of printer heads.

- Semiconductor & Electronics Manufacturing: Precise assembly and transfer systems.

- Medical Devices: Imaging, DNA sequencing platforms, and laboratory automation.

- Packaging & Logistics: Automatic sorters, visual inspection conveyors, carton packaging lines.

- Special Equipment: Aerospace assembly, optical instrument platforms.

Why Choose HEBEI YIDI's bearing linear guide Solutions?

- Precise Performance: Micron-level repeatability with advanced manufacturing.

- High Load: RGH65 supports up to 165 kN — ideal for heavy duty linear bearing slides.

- Customization Service: Choose from various sizes, slider combinations, and environmental treatments.

- Fast Logistics: Global delivery and trustworthy after-sales support.

- Professional Selection: YIDI provides selection support for bearing linear guide and double axis roller linear guide types.

- Quality Certification: ISO9001, CE compliant; products tested for bearing linear guide key indicators.

To buy linear guide rail or find a linear guide for sale with best-in-class precision, load, and competitive pricing — choose YIDI's Heavy Duty Linear Bearing Slide Rails RGH65.

Professional FAQ & Terminology

[source]

Industry References & Scientific Citations

- Motion Control Online Forum: Trends, technology insights, and user experiences for bearing linear guide (linear guides and ways).

- ScienceDirect: Precision Engineering Journal, "Analysis and optimization of rolling linear guide performance". [2020]

- Automation.com: Automation solutions and selection guides for linear guide rails.

- Linear Motion Tips: Expert guide to bearing linear guide materials and installation.

- Reportlinker: Global Linear Guides Market Report, 2021-2027 forecast.