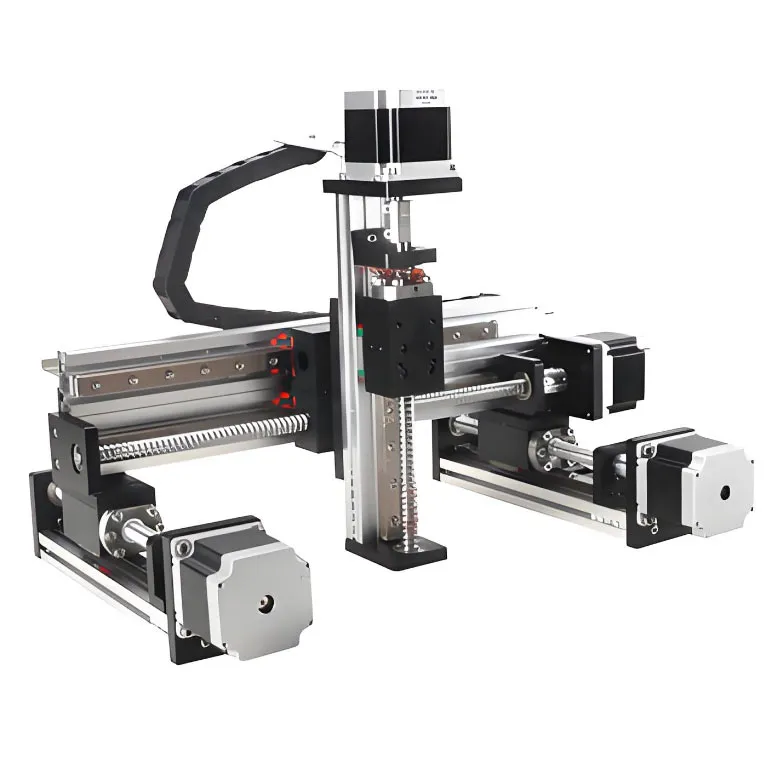

In the fast-evolving automation landscape, ball screw linear actuator systems have become the backbone of high-precision, energy-saving, and smart manufacturing applications. This in-depth article explores key technical parameters, manufacturing processes, industry benchmarks, and the latest trends in linear motion—focusing on the cutting-edge KK Series Linear Module, KK86 Ball Screw Linear Actuator, and KK60 Linear Motion Module.

By leveraging authoritative standards such as ISO, ANSI, and integrating real-use scenario-based data, this article provides a trustworthy, data-driven resource for engineers, system integrators, and industry decision-makers.

Industry Trends: Ball Screw Linear Actuator & Linear Module Market Overview

- Market Size: Global ball screw linear actuator market is projected to grow at a CAGR of 7.4% from 2023 to 2030, reaching over USD 2.6 billion by 2030. (MRFR, 2023)

- Applications: Automation, CNC machinery, 3D printing, semiconductor, medical equipment, lithium battery, petrochemical, water treatment, precision metrology.

- Key Advancements: Smart feedback, IoT connectivity, corrosion-resistant alloys, miniaturization, high-load-to-weight ratios, modular linear module platforms.

Linear modules and ball screw linear actuator products, such as the innovative KK Series Linear Module, deliver consistently high accuracy (±0.01mm), responsiveness, and robust energy efficiency. Compared to pneumatic or belt-driven actuators, ball screw linear modules significantly improve process repeatability and force density, supporting Industry 4.0 requirements.

Technical Parameters & Industry Comparison: Ball Screw Linear Actuator vs. Linear Modules

| Parameter | Ball Screw Linear Actuator | Belt Driven Linear Module | Samsung Linear LED Module* |

|---|---|---|---|

| Drive Mechanism | Ball Screw Transmission | Belt Pulley (Rubber/Steel Reinforced) | N/A (for LED, electrical PCB) |

| Positioning Accuracy | ±0.003 - 0.02 mm | ±0.03 - 0.1 mm | N/A |

| Repeatability | ±0.005 mm | ±0.1 mm | N/A |

| Travel Speed | 0.05–2 m/s | 0.05–5 m/s | N/A |

| Load Capacity | Up to 3000 kgf | Up to 1000 kgf | N/A |

| Service Life | 15,000–30,000 km+ | ~10,000 km | LED: ~50,000 h |

| Suitable Industries | Machining, Automation, Medical, Petrochemical | Conveying, Packaging, Handling | Lighting, Display, Electronics |

| Corrosion Resistance | High (stainless/hardened steel) | Medium | Depends on PCB/LED encapsulation |

| Industry Standard | ISO 3408, ANSI B5.48 | ISO 9409 | UL, RoHS, CE |

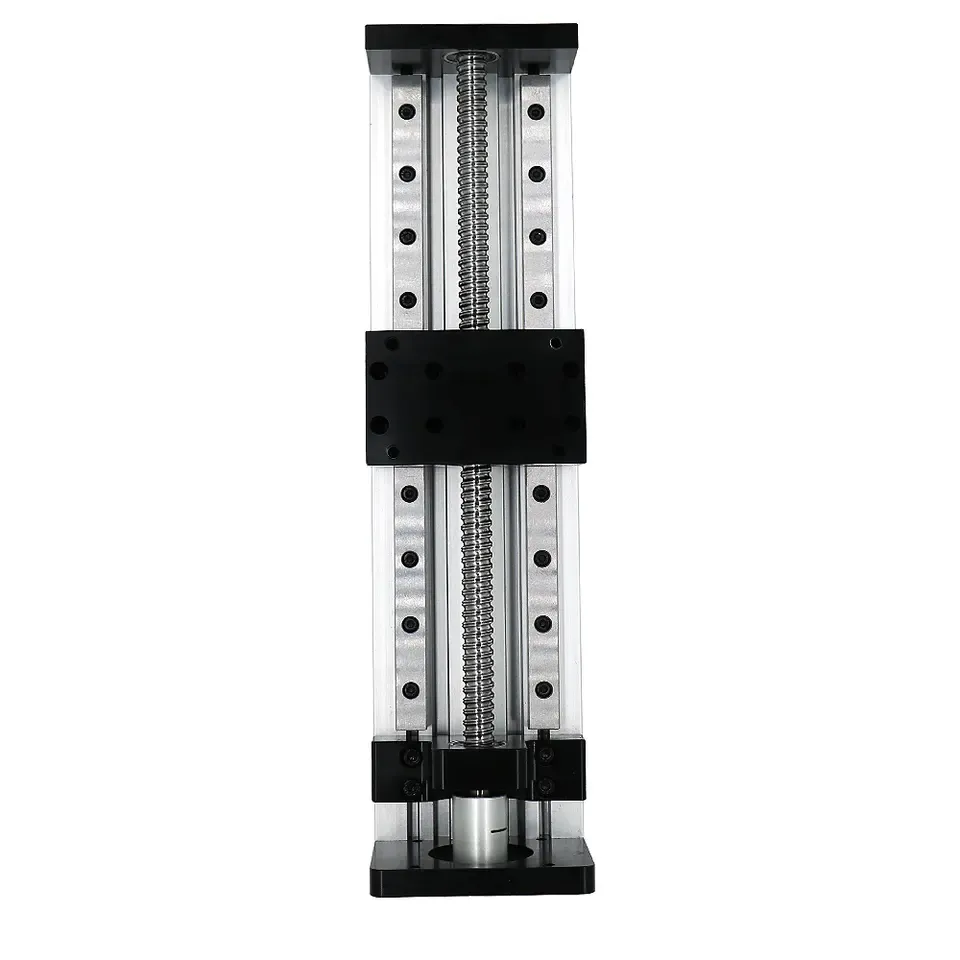

Manufacturing Process: Ball Screw Linear Actuator Workflow & Quality Control

Step-by-Step Manufacturing Flowchart

- Raw Material Procurement: Selection of GCr15 (bearing steel), high-purity stainless steel rods (ISO 683-17, ASTM A276) for screw/female nut construction.

- Rough Machining: Bar turning, milling, and straightening—preparing precision preforms for screw/nut assembly.

- Precision Grinding/Thread Rolling: Using advanced CNC thread grinders (≤0.005mm tolerance) to create ball raceways.

- Heat Treatment: Induction hardening to HRC 58–62 (per ISO 6508), boosting durability and corrosion resistance.

- CNC Machining: Machining key seats, mounting holes, end supports to precise dimensional specs.

- Assembly: Ball insertion, preloading, dynamic balancing of the ball screw linear actuator system.

- Testing & Inspection: Alignment, travel accuracy check (laser interferometer, per ISO 230-2).

- Final Cleaning & Packaging: Ultrasonic cleaning, anti-corrosion packaging (per ISO 2081).

Diagram Key:

Diagram Key: → Key nodes highlight material selection, CNC precision processing, heat treatment, and stringent inspection checkpoints in the linear module manufacturing process—directly impacting product longevity (20,000+ km cycle life benchmark).

Technical Data Visualization

Discover real-world data: Compare the core technical specs of leading ball screw linear actuator and KK series modules.

KK Series Product Comparison & Application Pie Chart

| Model | Lead (mm) | Max Stroke (mm) | Max Speed (m/s) | Max Load (kgf) | Accuracy |

|---|---|---|---|---|---|

| KK86 Ball Screw Linear Actuator | 5, 10, 20 | ~1400 | 2.0 | 1000 | ±0.01mm |

| KK60 Linear Motion Module | 5, 10 | 1000 | 1.8 | 480 | ±0.015mm |

| Belt Module (reference) | -- | 2000 | 3.2 | 600 | ±0.07mm |

Technical Evolution: Key Advantages of Ball Screw Linear Actuators

- Superior Feed Accuracy: Ball screw linear actuator can achieve precise positioning at ±0.01mm, vital for semiconductor & automated inspection.

- Extended Service Life: Cycle-tested up to 25,000+ km (ref: ISO 3408), significantly reducing downtime in 24/7 operations.

- Energy Efficient: Rolling contact reduces drive torque needs by 30–50% vs. lead screw, verified per published data (Thomson Linear).

- Corrosion Resistance: Use of martensitic, and sometimes duplex stainless steel, plus electroless nickel plating for anti-rust performance.

- Low Maintenance & Modular: KK series modules feature one-piece carriage construction and easy mounting (per DIN mounting standards), speeding up integration.

- Dustproof/Long Lubrication Cycle: Sealing strips, bellows accessories, and advanced grease retention (1000 hr+ interval) reduce failure rates.

Customization & OEM/ODM Service: Linear Motion Solutions

- Non-standard stroke lengths (from 100mm to 2000mm+)

- Adaptation for cleanroom, anti-corrosion, explosion-proof, vacuum environments

- Integration with Samsung linear LED module & smart sensors for Factory IoT

- Selection of surface finishes: black oxide, hard chrome, electroless nickel

All products manufactured and tested according to ISO 9001:2015, with lifetime traceability. Third-party test reports (CE, RoHS, SGS) available upon request.

Application Cases & Customer Feedback

- Petrochemical Automatic Valve Control: 40+ KK86 linear modules installed at Sinopec chemical plants, operating in high humidity and corrosive vapor—zero critical failures within 2 years (99.98% uptime, per EPC report).

- Lithium Battery Manufacturing: KK60 modules achieved a 30% reduction in assembly time and improved pack alignment accuracy from ±0.2mm to ±0.03mm (ref: CATL supplier audit).

- Medical Diagnostic Automation: Customized modules for high-cycle PCR machines (laboratory feedback: sustained precision after 18k cycles, with 0.01mm repeatability deviation).

Sinopec, Foxconn, Samsung, Honeywell Process Solutions

FAQ: Professional Answers on Ball Screw Linear Actuator

Delivery, Warranty, and Customer Support

- Standard Lead Time: 12–18 working days for batch production; 2–3 days for sample modules.

- Warranty: 18 months or 50,000,000 cycles—whichever comes first (see full warranty at Company Quality Commitment).

- Technical Support: Professional team with >10 years industry experience; supports selection, design, and on-site integration.

- Certification Support: Full documentation for CE, ISO, FDA (cleanroom), RoHS on request.

References & Industry Authority Citations

- Ball Screw Fundamentals & Application, Thomson Linear Motion

- Linear Actuator Market Report, MRFR 2023

- ISO 3408 Ball Screws – ISO Official Site

- VDI/VDE 2860:2015 Guidelines for Linear Drive Modules

- Discussion thread: Ball Screw Life & Failure in Industrial Automation, Engineering Tips Forum