DFU Ball Screw C3 Ball Screw And Double Nut technology is revolutionizing high-precision linear motion in the global industrial sector. As manufacturing demands surge for accuracy and efficiency, innovative products like the DFU series are rapidly becoming essential across diverse applications. In this comprehensive overview, we explore industry trends, technical highlights, application scopes, and expert perspectives—drawing on the latest research and market data.

About HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD.

- Official Website: https://www.ydmotion.com

- Phone: +86 18134111663

- Email: adam@yidimotion.com

- Mobile: +86 18134111662

- Address: 16-1-1601 Aobeigongyuan, Chang 'an District, Shijiazhuang City, Hebei Province, China

Product Overview: DFU Ball Screw C3 Ball Screw And Double Nut

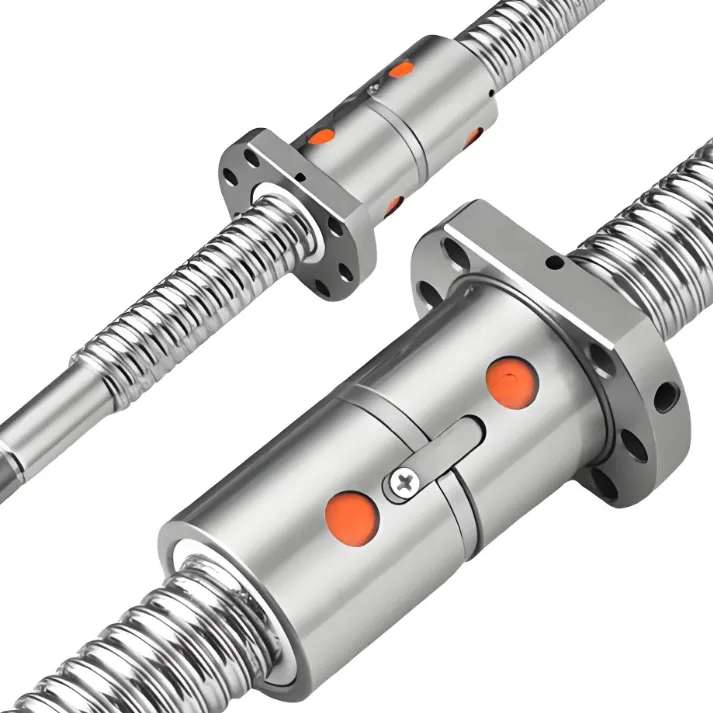

The DFU Ball Screw C3 Ball Screw And Double Nut is engineered with an internal circulation system (featuring circular/elliptical reversers) enabling ball circulation within the nut. This compact design achieves low noise operation while delivering precise, reliable linear motion. The double nut preloading design eliminates axial clearance, significantly enhancing positioning accuracy and repeatability—crucial for high-tech automation scenarios.

Product URL:

DFU Ball Screw C3 Ball Screw And Double Nut

Key Technical Parameters Table

| Parameter | Specification | Description |

|---|---|---|

| Model | DFU Ball Screw C3 | High-precision ball screw for critical motion control |

| Precision Grade | C3 | ISO/GB Standard; best for precise applications |

| Lead (mm) | 5, 10, 20 (Customizable) | Distance per screw revolution; accommodates speed or load needs |

| Screw Diameter (mm) | 12, 16, 20, 25, 32, 40 | Wide coverage for various machinery |

| Nut Type | Double Nut | Extra anti-backlash, enhances accurate positioning |

| Axial Clearance | 0 μm (Preload) | Near-zero play, best for demanding assembly lines |

| Dynamic Load Capacity (kN) | 7.3 ~ 94.2 | Varies per size, suitable for light to heavy duty |

| Static Load Capacity (kN) | 12.3 ~ 185.2 | Superior safety in static applications |

| Ball Diameter (mm) | 2.5 ~ 6.35 | High load transfer & smooth operation |

| Noise Level (dB) | <60 | Very quiet, ideal for electronics/medical use |

| Lubrication | Grease or Oil | Ensures consistent performance & durability |

| Temperature Range | -10°C to +80°C | Adaptable to a variety of working environments |

| Material | GCr15 (equivalent to AISI 52100) | Hardened chrome bearing steel |

Industry Trends & Market Demand

The global demand for DFU Ball Screw C3 Ball Screw And Double Nut technology is propelled by rapid advances in automation, CNC machining, robotics, and medical engineering. According to Linear Motion Tips Magazine, 2024 will see a 14% YoY increase in inquiries for precision ball screws, with C3 and double-nut designs leading the trend. This is attributed to their combination of low backlash, superior runout precision, and long service life—even in harsh industrial environments.

The ISO-compliant C3 grading ensures tight tolerances, making these screws indispensable in semiconductor, aerospace, and medical device fabrication. Technology adoption is driven by requirements for higher accuracy, quieter operation, and durability, all of which are hallmarks of the DFU Ball Screw C3 Ball Screw And Double Nut series.

Technology Highlights of DFU Ball Screw C3 Ball Screw And Double Nut

- Internal Ball Circulation (Circular/Elliptical Reverser): Achieves compact structure and superior noise reduction compared to external circulation systems (source).

- Double Nut Preloading: Opposing nuts are tensioned, eliminating axial clearance and maintaining sub-5μm repeatability.

- Chrome Bearing Steel (GCr15, AISI 52100 Equivalent): Ensures a hardened raceway, boosting load-bearing performance and longevity (reference).

- C3 Precision Grade (ISO/GB Standard): Guarantees lead accuracy within 8μm/300mm, matching global high-speed machinery needs.

- Zero Axial Backlash: Ideal for high-speed axis drives, pick & place robots, and optical assembly lines.

- Low Friction, High Speed: Rolling contact significantly reduces energy losses and heat generation.

- Versatile Lubrication Compatibility: Accepts standard synthetic greases or oil-mist lubrication systems, extending maintenance intervals.

Application Scenarios

- CNC Machine Tools: Ultra-precise axis positioning and fast traverse speeds for turning, milling, and EDMs.

- Semiconductor Production: Photolithography, wafer inspection, and component alignment demand sub-micron stability.

- Medical Equipment: Surgical robots, diagnostic scanning, and automated sample handling.

- 3D Printing and Robotics: Linear drives for multi-axis robots, delta printers, and motion platforms.

- Aerospace Engineering: Actuator assemblies for aircraft manufacturing, satellites, and UAV control systems.

- Automated Assembly Lines: Positioning modules, conveyor indexes, and press automation.

- Laser Engravers and Optical Inspection: Precise, repeatable motion for scanning and alignment in electronic and photonics industries.

Expert FAQ: Technical Terms for DFU Ball Screw C3 Ball Screw And Double Nut

Q1: What is the main advantage of using a double nut system for ball screws?

A: The double nut design effectively eliminates axial backlash by preloading against each other. This results in higher positioning accuracy and stability, essential in applications requiring micron-level precision (Source).

Q2: Why is C3 precision grade important in modern industry?

A: C3 is an ISO/GB recognized precision class, guaranteeing lead deviation under 8μm per 300mm. This ensures ultra-smooth, consistent motion, which is vital for high-end CNC, semiconductor, and aerospace equipment.

Q3: What is the commonly used material for DFU ball screws?

A: High carbon chromium bearing steel (GCr15, equivalent to AISI 52100) is most common, featuring through-hardened or induction-hardened surfaces for abrasion and fatigue resistance.

Q4: How is preloading achieved in DFU Ball Screw C3 Ball Screw And Double Nut?

A: By assembling two nuts with an intentional offset or spacer, tension is created that cancels axial clearance, delivering close-to-zero backlash—a necessity for precision automation.

Q5: What is internal ball circulation and why does it matter?

A: The internal ball circulation system (circular/elliptical reversers) allows the recirculation path to stay within the nut body, reducing noise, size, and risk of contamination compared to external tube circuits.

Q6: Are there industry standards for installation fit and tolerance?

A: Yes. Ball screws comply with international standards like ISO 3408 and GB/T 17587.3, ensuring compatibility in mounting, preloading, and axial alignment.

Q7: How is lubrication handled in these systems?

A: Lubrication can be via conventional grease, automatic oilers, or oil-mist systems. Proper lubrication prolongs service life, reduces heat, and ensures peak performance.

Why Choose DFU Ball Screw C3 Ball Screw And Double Nut from HEBEI YIDI?

- Superior Engineering: Rigorous quality control and advanced grinding ensure each screw/nut meets C3 accuracy.

- Customization: Tailored leads, diameters, and nut configurations are available to fit your project needs.

- After-Sales Support: Responsive technical assistance and global logistics.

- Compliance: Full adherence to ISO/GB, RoHS, and CE standards.

- Competitive Pricing: As a factory-direct supplier, HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD. offers market-leading value.

Summary & Further Reading

The DFU Ball Screw C3 Ball Screw And Double Nut series represents the pinnacle of motion accuracy, stability, and reliability required for next-generation manufacturing and automation. With internal circulation, double nut design, and C3 precision, these ball screws are redefining expectations in CNC, robotics, and high-end equipment globally.

Contact HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD. today for expert solutions tailored to your precision engineering needs.

References & Industry Sources:

[1] Linear Motion Tips: Ball Screw Technology Trends, 2024

[2] Hindawi Journal: Low-Noise Ball Screws via Internal Circulation

[3] Springer: Material Analysis of High-Accuracy Ball Screws

[4] Machine Design: The Why and How of Preloaded Ball Screws

[5] Industry Forums: ENG-TIPS Forums: Ball Screw Discussions