Advancing Precision Motion: The Core Role of Ball Screw Linear Actuator Technology

In the rapidly evolving landscape of industrial automation, the demand for highly precise, reliable, and efficient motion control systems is paramount. At the heart of many advanced manufacturing and processing operations lies the ball screw linear actuator, a critical component that converts rotary motion into precise linear movement. These actuators are indispensable across diverse sectors, from semiconductor fabrication to complex robotic systems, where accuracy and repeatability are non-negotiable. Their inherent design, featuring a precision-ground ball screw and nut assembly, minimizes friction and backlash, offering superior positioning accuracy and smooth operation compared to traditional lead screw mechanisms. This foundational technology underpins the performance of various linear motion solutions, including advanced linear modules designed for high-throughput and demanding environments.

The continuous innovation in materials science and manufacturing techniques further enhances the capabilities of these actuators, pushing boundaries in speed, load capacity, and operational lifespan. Understanding the intricate details of their design, manufacturing processes, and application specific advantages is crucial for B2B decision-makers and technical personnel aiming to optimize their automation infrastructure. This article delves into the specifics of ball screw linear actuator technology, highlighting its technical prowess, diverse applications, and the strategic considerations for selecting the most suitable solutions for modern industrial challenges. We will explore how solutions like the KK Series Linear Module KK86 Ball Screw Linear Actuator KK60 Linear Motion Module exemplify the pinnacle of engineering in this field.

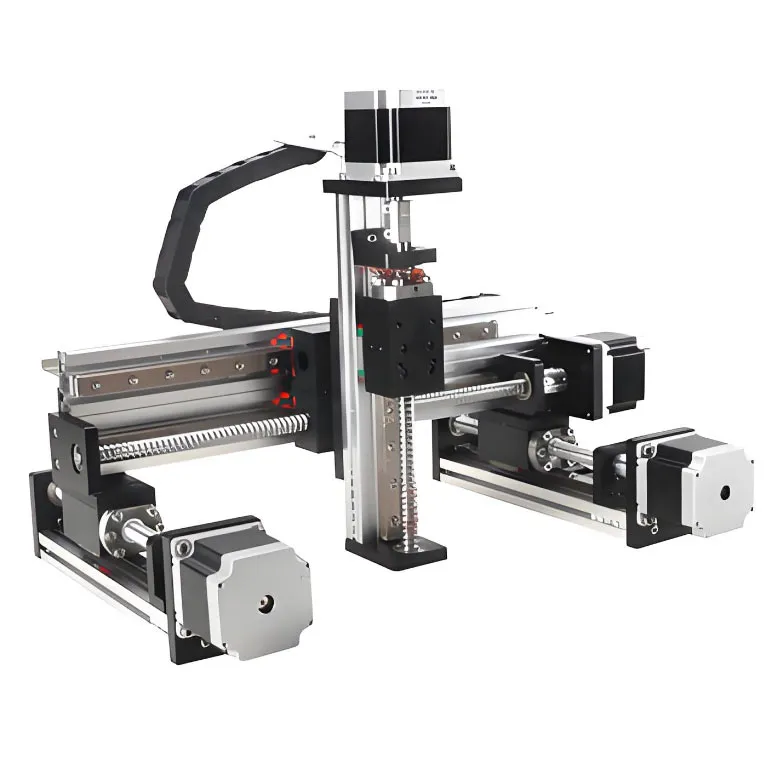

Introducing the KK Series Linear Modules: KK86 and KK60

The KK Series Linear Module, encompassing models like the KK86 Ball Screw Linear Actuator and the KK60 Linear Motion Module, represents a pinnacle in integrated linear motion solutions. These modules are engineered to provide exceptional precision, rigidity, and versatility within a compact form factor, making them ideal for a broad spectrum of industrial applications. The KK86, with its robust design, offers higher load capacities and greater rigidity, catering to demanding tasks requiring substantial force and stability. Conversely, the KK60 is optimized for applications where space is at a premium but high precision and dynamic performance remain critical. Both models leverage advanced ball screw technology, ensuring minimal friction and backlash, which translates directly into superior positioning accuracy and smooth, quiet operation. The integration of the drive mechanism and guiding system into a single unit simplifies machine design, reduces assembly time, and enhances overall system reliability.

These linear modules are designed to integrate seamlessly into existing automation frameworks, providing a complete motion solution from a single source. Their enclosed design protects internal components from dust and debris, extending service life and reducing maintenance needs, particularly in harsh industrial environments. Key features include high repeatability, excellent straightness and parallelism, and the ability to operate at high speeds. The choice between the KK86 and KK60 often depends on the specific requirements of the application, including payload, required stroke length, speed, and environmental conditions. Both versions uphold a commitment to precision engineering, ensuring consistent and reliable performance for critical manufacturing and assembly processes.

The Precision Craftsmanship: Manufacturing Process of a Ball Screw Linear Actuator

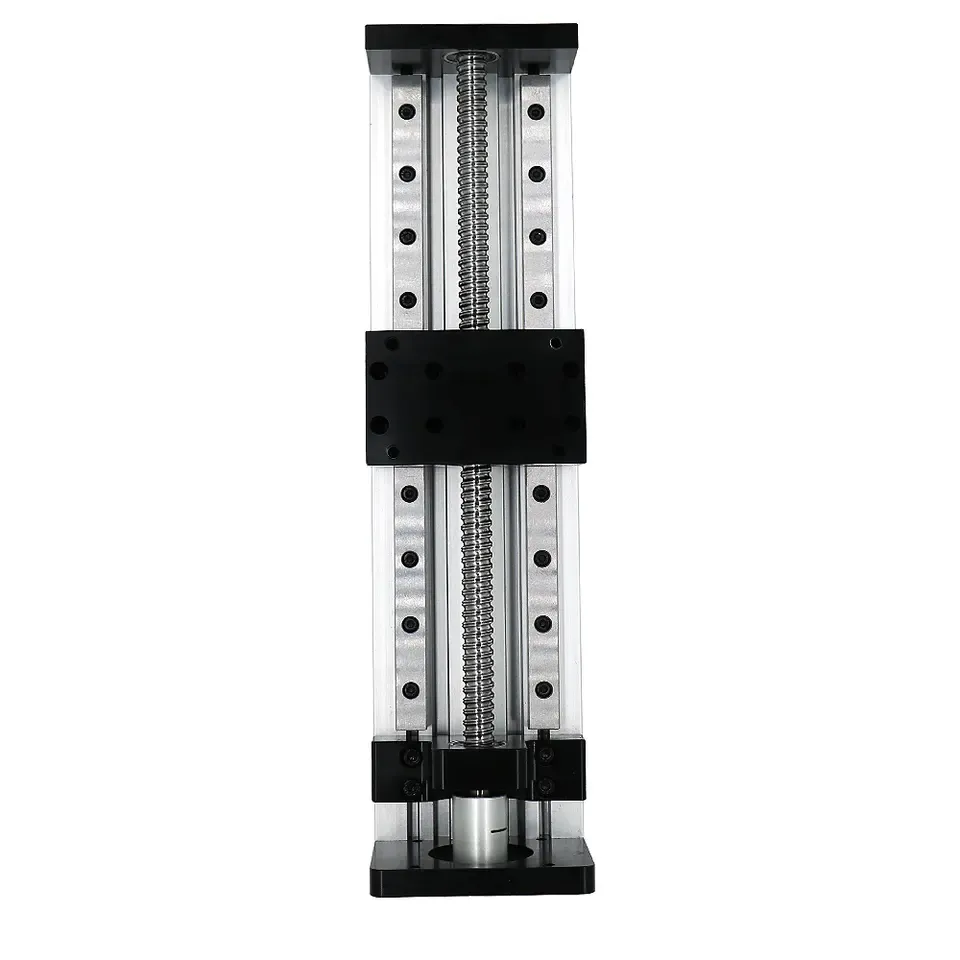

The manufacturing of a high-quality ball screw linear actuator is a complex process demanding meticulous attention to detail and advanced engineering techniques. It begins with the selection of premium materials, typically high-grade alloy steels for the screw shaft and nut, chosen for their hardness, wear resistance, and fatigue strength. The core components, such as the screw shaft, often undergo precision forging or rolling, followed by intricate CNC machining to achieve the precise helical groove profile necessary for smooth ball recirculation. This critical stage is typically followed by heat treatment processes, including hardening and tempering, to achieve the desired material properties and extend service life. For high-precision applications, the screw shaft undergoes a rigorous grinding process, ensuring surface finish and lead accuracy that meet stringent industry standards.

The ball nut manufacturing involves equally precise machining and assembly of the ball return system. After individual components are formed, they undergo rigorous quality control, adhering to international standards such as ISO (International Organization for Standardization) for dimensional tolerances and ANSI (American National Standards Institute) for material specifications. Each ball screw linear actuator is subjected to comprehensive testing, including lead accuracy measurements, backlash assessment, and dynamic load testing to verify performance against design specifications. Typical service life for well-maintained ball screw actuators can range from tens of thousands to hundreds of millions of cycles, depending on load, speed, and environmental conditions. This rigorous manufacturing and testing regimen ensures that each unit delivers reliable, high-performance operation, critical for industries such as petrochemical, metallurgy, water treatment, and general industrial automation, where precision and durability are paramount for optimal operation and reduced energy consumption. The inherent low friction of ball screw designs also contributes to significant energy savings over prolonged operational periods.

Furthermore, specific treatments like anti-corrosion coatings are applied for actuators intended for harsh environments, such as those found in chemical processing or offshore applications. This layered approach to manufacturing, from raw material selection to final quality checks, ensures that each ball screw linear actuator not only meets but often exceeds the demanding performance expectations of industrial users, delivering long-term value and operational efficiency. The integration of advanced diagnostics and predictive maintenance features is also becoming standard, allowing for proactive servicing and minimizing downtime in critical industrial processes.

Key Technical Specifications and Performance Metrics for Ball Screw Linear Actuators

When selecting a ball screw linear actuator, understanding its technical specifications and performance metrics is crucial for ensuring it meets the application's precise requirements. Key parameters define the actuator's capabilities and limitations. Lead Accuracy refers to the precision with which the linear position corresponds to the angular rotation of the screw. For high-precision applications, ground ball screws typically offer lead accuracies ranging from C0 (0.003 mm per 300 mm) to C7 (0.05 mm per 300 mm), directly impacting the overall system's positioning precision. Repeatability, another critical metric, indicates how consistently the actuator can return to a specific position; values often range from ±0.003 mm to ±0.01 mm, signifying the system's ability to perform repetitive tasks with minimal deviation.

Dynamic Load Capacity (Ca) and Static Load Capacity (Coa) define the maximum load an actuator can withstand during operation and at rest, respectively, while maintaining its specified lifespan. These values are typically provided in Newtons (N) or kilonewtons (kN) and are vital for preventing premature wear or failure. Maximum Speed, often expressed in meters per second (m/s) or millimeters per second (mm/s), determines the actuator's operational velocity. The Stroke Length specifies the maximum linear travel distance, while the Screw Lead (the linear distance traveled by the nut for one complete revolution of the screw) dictates the trade-off between speed and force. A larger lead offers higher speed but lower force, and vice-versa. Understanding these parameters is essential for engineers to design and implement efficient and reliable motion control systems for various industrial applications.

Typical Ball Screw Linear Actuator Parameters

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Screw Diameter (Dk) | Nominal diameter of the ball screw shaft. | 16mm - 63mm (e.g., KK60 might use 16-20mm, KK86 25-40mm) |

| Screw Lead (P) | Linear travel per revolution of the screw. | 5mm, 10mm, 20mm, 40mm, 50mm |

| Lead Accuracy (Cp) | Deviation from ideal lead over a given length. | C0 (0.003mm/300mm) to C7 (0.05mm/300mm) |

| Repeatability | Consistency of returning to a position. | ±0.003mm to ±0.01mm |

| Max. Dynamic Load (Ca) | Maximum allowable load during operation. | 5 kN - 50 kN (varies significantly with size) |

| Max. Speed | Maximum linear velocity. | Up to 2 m/s (higher for some specialized designs) |

| Max. Stroke Length | Maximum achievable linear travel. | 100mm - 4000mm+ |

| Lifetime (L10) | Operating distance before 10% of units fail. | Typically millions of revolutions/thousands of km |

These parameters are fundamental for system integrators and design engineers in determining the suitability of a ball screw linear actuator for specific tasks, balancing performance, durability, and cost-effectiveness. Careful consideration of these technical specifications ensures optimal system performance and longevity in demanding industrial environments.

Diverse Applications and Key Technical Advantages

The versatility and precision of the ball screw linear actuator make it an indispensable component across a multitude of industries. In Industrial Automation, they are the backbone of pick-and-place robots, CNC machine tools, and automated assembly lines, ensuring high-speed, accurate positioning for repetitive tasks. The Semiconductor Industry relies heavily on their ultra-high precision for wafer handling, inspection, and packaging equipment, where even micron-level inaccuracies can compromise product quality. In the Medical and Pharmaceutical sectors, ball screw linear actuators are crucial for dispensing systems, laboratory automation, and diagnostic equipment, demanding sterile environments and precise fluid control. Their robust construction also makes them suitable for harsh conditions found in Petrochemical and Metallurgy industries, driving critical valves, dampers, and material handling systems, often incorporating corrosion-resistant materials for longevity.

Beyond these, their application extends to Water Treatment plants for precise flow control and valve operation, and in Renewable Energy for solar panel tracking systems or wind turbine pitch control. The technical advantages of using a ball screw linear actuator are significant: their low friction design drastically reduces energy consumption compared to hydraulic or pneumatic systems, leading to substantial energy savings over operational lifecycles. Their inherent precision ensures minimal backlash and high repeatability, which are vital for processes requiring exact positioning. Furthermore, specialized coatings and material selections provide exceptional corrosion resistance, extending the actuator's life in aggressive chemical or marine environments. The robust design and high load capacity ensure reliability and durability, reducing maintenance costs and downtime, which are critical factors for industrial productivity and efficiency.

The integration of a linear motion module, especially the KK Series, streamlines these advantages into a single, compact unit, providing comprehensive solutions for complex motion control requirements. This modularity not only simplifies system design but also enhances overall performance and reliability, offering a robust and adaptable solution for future industrial growth and technological advancements.

Manufacturer Comparison and Custom Solutions: Why YD Motion Stands Out

In a competitive global market, discerning the right manufacturer for your ball screw linear actuator needs is crucial. While many providers offer standard products, YD Motion distinguishes itself through a steadfast commitment to engineering excellence, bespoke customization, and unparalleled customer support. Our comprehensive understanding of diverse industrial demands allows us to go beyond off-the-shelf solutions, crafting linear modules that precisely integrate with your unique application requirements. This focus on tailored engineering ensures optimal performance, efficiency, and longevity, mitigating the common compromises associated with generic components. Our expertise spans from high-speed pick-and-place systems to heavy-duty material handling, leveraging our KK Series Linear Module and other specialized linear module solutions.

YD Motion's competitive advantage is rooted in several key areas. Firstly, our advanced manufacturing capabilities, including precision CNC machining and rigorous quality control protocols, ensure that every ball screw linear actuator meets the highest standards of accuracy and durability. Secondly, we offer extensive customization options: from specific stroke lengths, screw leads, and mounting configurations to specialized materials for harsh environments (e.g., stainless steel for corrosion resistance), and integrated control systems. This flexible approach allows clients to achieve precise functionality without costly modifications or compromises. Thirdly, our dedicated team of engineers collaborates closely with clients from concept to implementation, providing expert guidance and technical support throughout the entire project lifecycle. This partnership model ensures that the selected linear motion module is not just a component, but a perfectly integrated solution that enhances overall system performance and operational efficiency.

Our track record of successful implementations across various industries, coupled with positive client feedback, stands testament to our ability to deliver superior ball screw linear actuator solutions. By choosing YD Motion, clients gain a partner committed to innovation, quality, and precision, ensuring their automation investments yield maximum returns and long-term reliability. We pride ourselves on creating linear modules that are not just products, but integral parts of our clients' success stories.

Real-World Application Cases and Customer Success

The practical effectiveness of a ball screw linear actuator is best demonstrated through its successful deployment in real-world industrial settings. One notable application involves a leading automotive manufacturing plant that integrated KK Series Linear Modules into their automated welding cells. The high precision and repeatability of the KK86 Ball Screw Linear Actuators enabled robotic arms to execute complex welding patterns with micron-level accuracy, significantly reducing material waste and improving weld quality. This transition resulted in a 20% increase in production throughput and a noticeable reduction in post-production rework, directly impacting their operational efficiency and cost savings. The robust design of the linear modules also ensured continuous operation in a harsh environment, showcasing their durability and reliability under constant heavy loads and high-speed cycles.

Another compelling example comes from the food packaging industry, where KK60 Linear Motion Modules were adopted for a high-speed pick-and-place system. This application demanded rapid, precise, and gentle handling of delicate food products. The compact form factor and quiet operation of the KK60, combined with its exceptional speed and low vibration, allowed for efficient product transfer without damage, reducing spoilage by 15%. According to feedback from the client, "The linear modules from YD Motion have transformed our packaging line. Their consistent performance and minimal maintenance requirements have significantly contributed to our uptime and overall productivity." These tangible benefits underscore the direct correlation between the quality of the ball screw linear actuator and the operational success of complex automated systems. Such application cases highlight not only the technical prowess but also the real-world value and return on investment offered by YD Motion's linear motion solutions.

The diverse range of successful deployments, from heavy industrial machinery to delicate laboratory equipment, solidifies the reputation of YD Motion's ball screw linear actuator products as reliable, high-performance solutions for the most demanding applications. Our engineering team meticulously analyzes each client's unique challenges, proposing and delivering optimized linear module systems that consistently exceed expectations in terms of precision, speed, and long-term durability.

Ensuring Trust: Quality Assurance, Certifications, and Support

Trust is the cornerstone of any successful B2B partnership, particularly when dealing with precision components like a ball screw linear actuator. YD Motion is steadfast in its commitment to quality, a commitment reinforced by robust quality management systems and adherence to international standards. Our manufacturing facilities are ISO 9001 certified, ensuring that every stage of production, from raw material sourcing to final assembly and testing, adheres to stringent quality protocols. This certification provides clients with the assurance that our processes are standardized, efficient, and focused on continuous improvement, resulting in consistent product quality. Furthermore, our linear modules undergo comprehensive performance validation tests, including fatigue testing, load deflection analysis, and environmental simulations, to ensure they meet and exceed published specifications. We also comply with relevant industry-specific certifications and safety standards, where applicable, providing a comprehensive assurance of product reliability and safety.

YD Motion stands by the quality of its products with a comprehensive warranty program that covers manufacturing defects and material failures for a specified period, typically one to two years from the date of purchase. Our transparent delivery cycle commitment ensures that clients receive their orders promptly and reliably, minimizing potential project delays. For standard ball screw linear actuator and linear module configurations, typical lead times range from 2 to 4 weeks, with expedited options available for urgent requirements. Custom solutions, depending on complexity, are quoted with clear timelines upfront. Our dedication to customer support extends beyond sales, offering comprehensive technical assistance, troubleshooting, and maintenance guidance through dedicated channels. This includes access to experienced engineers who can assist with installation queries, operational optimization, and long-term service needs, ensuring the sustained performance of your linear motion systems.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for KK Series Linear Modules?

A: Standard configurations typically ship within 2-4 weeks. Custom designs will have a lead time quoted based on complexity. - Q: Can your linear actuators operate in harsh environments (e.g., high temperature, corrosive)?

A: Yes, we offer specific material options (e.g., stainless steel, special coatings) and designs tailored for high temperature, corrosive, or cleanroom environments. Please consult with our engineering team for specialized solutions. - Q: What is the expected service life of a ball screw linear actuator?

A: The service life depends on load, speed, and maintenance. Under specified operating conditions and with proper lubrication, our actuators are designed for millions of cycles or tens of thousands of kilometers of travel, quantified by L10 life ratings. - Q: Do you provide integration support for your linear modules?

A: Absolutely. Our technical support team is available to assist with integration, programming, and optimization of our linear modules into your existing or new automation systems.

The Future of Linear Motion: Trends and Innovations

The field of linear motion technology, particularly concerning the ball screw linear actuator, is continuously evolving, driven by advancements in smart manufacturing, Industry 4.0, and the increasing demand for automation. Key trends include the development of more compact and lightweight linear module designs without compromising on load capacity or precision, facilitating their integration into smaller, more agile robotic systems. There's also a significant push towards enhanced connectivity and predictive maintenance capabilities, with integrated sensors providing real-time data on performance, temperature, and vibration. This allows for proactive maintenance scheduling, minimizing downtime and optimizing operational efficiency, crucial for critical production lines. The integration of advanced control algorithms and artificial intelligence is further refining the precision and adaptability of linear motion systems, enabling them to handle more complex and dynamic tasks.

The quest for greater energy efficiency remains a driving force, with manufacturers focusing on lower friction designs and more efficient motor integration. Materials science continues to play a vital role, leading to components that offer superior wear resistance and durability in extreme environments. As industries move towards more sustainable practices, the long operational lifespan and repairability of ball screw linear actuator systems are becoming increasingly important. YD Motion remains at the forefront of these innovations, continually investing in research and development to ensure our linear module offerings, including the KK Series, meet the demands of future industrial automation challenges, providing high-performance, intelligent, and sustainable linear motion solutions.

References

- International Organization for Standardization. (2018). ISO 9001:2015 Quality management systems — Requirements.

- Schmid, P. (2020). Precision Machine Design and Manufacturing. Cambridge University Press.

- Wang, L., & Xi, F. (2019). Advances in Linear Motion Systems for Precision Manufacturing. Journal of Manufacturing Science and Engineering, 141(10).

- ASME. (2017). ANSI/ASME B5.48-2017: Ball Screws – Guide for Precision Ball Screws.

- Robotics and Automation Society. (2021). The Handbook of Robotics. Springer.