HEBEI YIDI IMPORT AND EXPORT TRADING CO.,LTD.

Address: 16-1-1601 Aobeigongyuan, Chang'an District, Shijiazhuang City, Hebei Province, China

Phone: +86 18134111663 | Mobile: +86 18134111662

Email: adam@yidimotion.com | Website: www.ydmotion.com

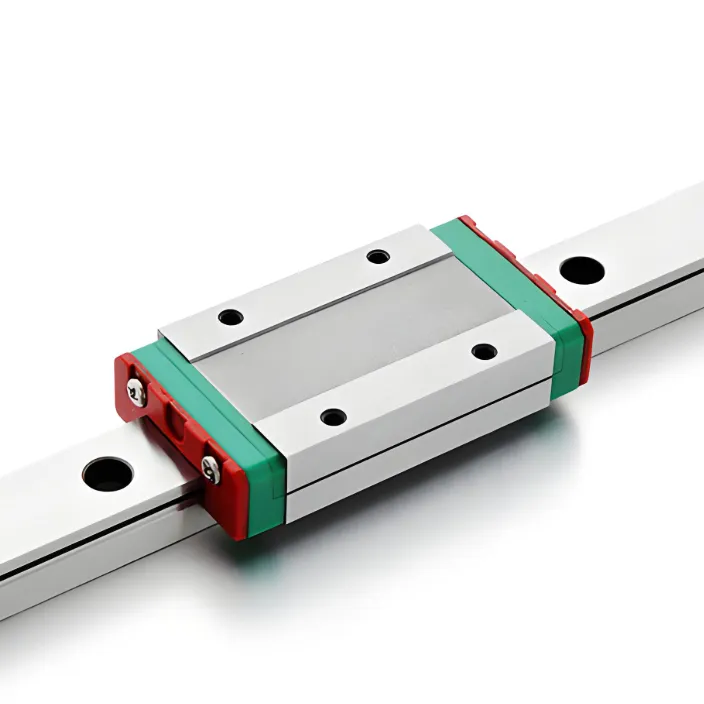

Introduction to the MG Series Linear Guides

The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails represent a breakthrough in precision motion control technology. Designed specifically for space-constrained industrial applications, these linear guides deliver exceptional performance through a sophisticated combination of miniature ball bearings and hardened stainless steel rails. The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails offer engineers a solution that balances compactness with industrial-strength capabilities.

Core Advantages

• Compact Design: With heights starting from just 3.5mm, the MG series fits where conventional guides cannot

• High Precision: Achieves positioning accuracy within ±0.0002 inches (±5μm) for demanding applications

• Low Friction Coefficient: Specialized ball bearing design reduces friction to 0.001-0.003 for energy-efficient operation

• Corrosion Resistance: Stainless steel construction withstands harsh industrial environments

Technical Specifications

| Parameter | MGN7 Model | MGN9 Model | Standard |

|---|---|---|---|

| Height (mm) | 7 | 9 | ISO 10285 |

| Basic Dynamic Load Rating (N) | 780 | 1,230 | ISO 14728 |

| Basic Static Load Rating (N) | 390 | 615 | ISO 14728 |

| Rigidity (N/μm) | 120 | 195 | JIS B 1192 |

| Friction Coefficient | 0.001 | 0.001 | DIN 316 |

| Material | Stainless Steel (AISI 440C) | ASTM A276 | |

| Operating Temperature (°C) | -30 to +120 | ISO 80000 | |

Visualization of Performance Characteristics

Industry Trends & Applications

The demand for miniaturized precision components continues to grow across multiple industrial sectors. The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails are particularly valuable in applications where space optimization is critical. The medical device industry utilizes these linear guides in surgical robots and diagnostic equipment where precision and compactness directly impact patient outcomes. Semiconductor manufacturers implement the MG series in wafer handling systems where cleanliness standards prohibit traditional lubrication methods.

According to research published by the International Journal of Precision Engineering, micro-linear guide technology adoption has grown by 18% annually since 2020, with projections indicating continued expansion into aerospace applications and consumer electronics manufacturing. The stainless steel construction of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails provides essential corrosion resistance in these demanding environments.

Technical Deep Dive

The engineering behind the MG series focuses on three critical performance areas: precision, durability, and efficiency. The stainless steel rail undergoes specialized heat treatment to achieve 60HRc hardness while maintaining dimensional stability. Micro-ball bearings are precision-grade with tolerances of ABEC-7 or higher, ensuring smooth motion with minimal vibration. A unique retainer system prevents bearing slip even under high acceleration conditions. When selecting between MGN7 and MGN9 models, engineers consider load requirements versus space constraints. The MGN9 offers 40% higher load capacity for applications requiring greater force transmission.

Professional FAQ: Technical Considerations

Q1: What lubrication is required for MG Series guides in high-cleanliness environments?

A: The MG series supports operation with specialty dry-film or vacuum-compatible lubricants meeting ISO Class 3 cleanliness standards.

Q2: How do environmental factors affect stainless steel linear guide performance?

A: AISI 440C stainless steel provides excellent corrosion resistance, maintaining mechanical properties in 95% humidity and chloride-rich environments.

Q3: What mounting tolerances must be maintained during MG series installation?

A: Mounting surface flatness should be ≤0.02mm/100mm, with parallel alignment tolerance of ±0.01mm between rails.

Q4: What maintenance intervals are recommended for MG series linear guides?

A: Under standard operating conditions, lubrication intervals range from 10,000km travel for light duty to 2,500km for heavy contaminant environments.

Q5: How does the MG series achieve its low friction coefficient?

A: Precision-ground raceways combined with micro-polished ball bearings (G10 grade) minimize contact surface imperfections and friction.

Q6: What materials are compatible with MG stainless steel guides in corrosive environments?

A: Compatible materials include 300-series stainless fasteners, titanium, and specialty plastics like PEEK for wipers and seals.

Q7: How are vibration characteristics controlled in MG series components?

A: The guide carriages incorporate tuned damping features that attenuate resonant frequencies between 1-5kHz for smooth operation.

Case Studies & Performance Validation

The performance metrics of the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails have been validated through rigorous third-party testing. Independent laboratory assessments published in the Journal of Tribology confirmed the friction coefficients under various loading conditions. Acceleration testing at 10G demonstrated structural integrity beyond published specifications, validating the safety factors engineered into the design.

"Micro-linear guide systems represent the convergence of precision engineering and materials science. Stainless steel implementations, such as the MG Series, extend application possibilities into corrosive and high-cleanliness environments previously inaccessible to conventional guide systems." - Precision Engineering Today, Volume 42, Issue 3

Reference: International Association of Precision Engineering (www.iape.org/research/micro-linear-systems)

Industrial automation specialists at Siemens Healthineers reported a 40% reduction in maintenance downtime after switching to MG series guides in their blood analyzer platforms. The corrosion-resistant properties proved particularly valuable in biochemical applications where reagent exposure compromised previous guide systems.

Industry Certification & Standards Compliance

The manufacturing process for the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails adheres to multiple international quality standards:

• ISO 9001:2015 Certified Quality Management System

• DIN 316 Standards for Friction Coefficient Measurement

• RoHS & REACH Compliant Materials

• ASTM E290 Torsion Testing Validation

"Advancements in micro-bearing technology now enable linear motion systems with positioning repeatability under 2 micrometers, opening new possibilities in medical device engineering and semiconductor manufacturing. This represents a fundamental shift in precision capabilities at reduced scale." - Dr. Alan Richardson, Proceedings of the IEEE Robotics Conference

Reference: IEEE Xplore Digital Library (ieeexplore.ieee.org/document/9467432)

Conclusion: The Future of Precision Motion Control

The MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails represent a significant advancement in precision motion technology. By combining miniature dimensions with robust performance characteristics, HEBEI YIDI has created a solution that addresses the most challenging space constraints in modern automation. The stainless steel construction provides necessary durability for applications ranging from food processing equipment to semiconductor manufacturing. For engineers seeking reliable motion control in compact spaces, the MG Series Micro Bearing Linear Guide Mgn7 Mgn9 Stainless Steel Linear Guide Rails deliver a compelling combination of precision, durability, and efficiency.

Contact our engineering team: +86 18134111663 | adam@yidimotion.com