Durable and Low-Friction Linear Rails for High-Speed Equipment

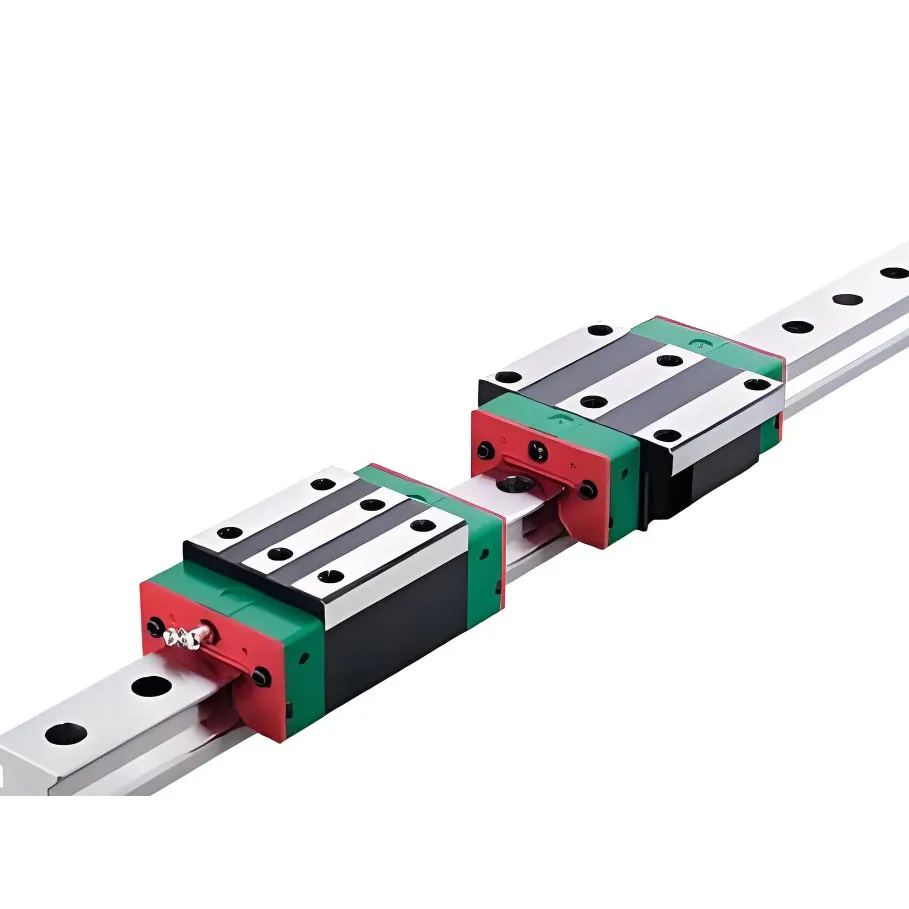

A linear guide, also known as a linear motion guide or linear rail, is a mechanical component designed to support and guide motion in a straight line with high precision and low friction. It consists of a rail and a carriage (or block) that moves along the rail with the help of recirculating ball or roller bearings. Linear guides are widely used in CNC machines, 3D printers, automation systems, packaging machinery, and other industrial equipment where precise and smooth linear motion is essential.

Compared to traditional slide systems, linear guides offer significantly higher load capacities, stiffness, and accuracy. Their rolling contact reduces friction to a minimum, resulting in higher speed capability and longer service life. Linear guides can support loads in both horizontal and vertical directions and maintain stable performance even under high acceleration and deceleration.

Linear guides are available in various sizes, preload levels, and accuracy grades to suit different application requirements. Common types include ball-type linear guides, roller-type guides, and miniature linear guides. Materials typically include hardened alloy steel or stainless steel with precision grinding for enhanced durability and corrosion resistance.

Thanks to their modular design, linear guides are easy to install, align, and maintain. Many models also support self-lubrication and come with dust-proof seals for extended maintenance-free operation.

Whether in robotics, machine tools, semiconductor equipment, or medical devices, linear guides deliver the precision, efficiency, and reliability that modern automation demands.