-

Products Feature

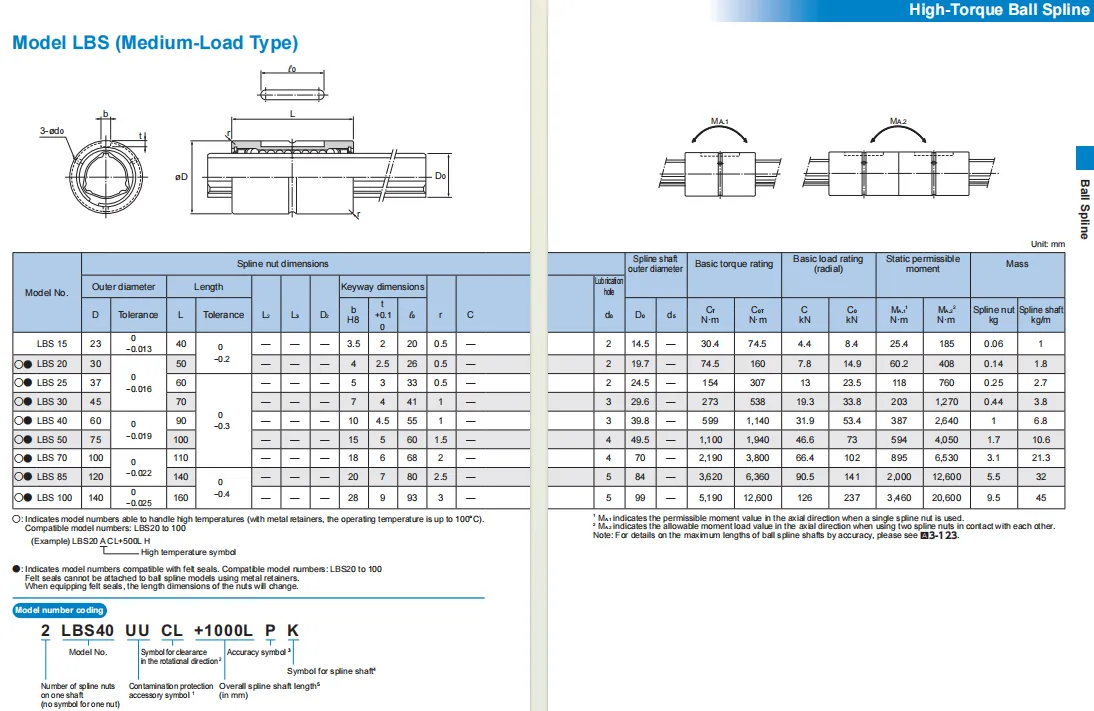

Three protrusions are evenly arranged at 120 ° on the outer ring of the spline shaft, and two rows (a total of six rows) of steel balls are arranged to clamp them from the left and right sides. The contact part of the steel ball is an angular contact structure, which makes it easy to apply preloading to it.

Due to the fact that the circulation of steel balls occurs at the inner diameter of the spline nut.

Therefore, the outer diameter of the spline nut can be miniaturized.

Even with increased preload, smooth linear rolling motion can be achieved.

Due to the large contact angle (45 °) and small displacement, high rigidity can be achieved.

There is no gap in the direction of rotation.

Capable of transmitting high torque.

-

Products Advantage

High precision and high repeatability positioning accuracy: Through precision machining and ball circulation structure, LBS ball splines can achieve micrometer level errors. Its gapless design eliminates axial and radial clearances through preloading adjustment, ensuring stability of motion and repeat positioning accuracy, making it particularly suitable for precision machining and measuring equipment

Low friction and high transmission efficiency: LBS ball splines use rolling friction, with a friction coefficient only 1/50~1/30 of traditional sliding splines, significantly reducing energy loss. This design achieves a transmission efficiency of over 90%, making it suitable for high-speed and long stroke movements, such as high-speed transmission in automated production lines

High load-bearing capacity and high rigidity: The rolling groove of LBS ball spline is precision ground and formed, and adopts a 40 ° angle contact, making it have a large load capacity in both radial and torque directions. The high contact angle endows it with the characteristic of high rigidity, which can maintain high rigidity during transmission and adapt to impact or vibration environments

Wear resistance and long service life: LBS ball spline adopts rolling contact, reducing material loss, and the service life can reach more than 10 times that of traditional splines. Its sealed dust-proof design prevents dust and debris from entering, further extending its service life

Composite motion capability: LBS ball spline can perform both rotational and linear motion simultaneously, simplifying the mechanical structure.

Strong adaptability and easy installation: LBS ball splines can adapt to various harsh environments such as high temperature, high pressure, and corrosion, and are easy to install, reducing the complexity of production and maintenance

-

Products Application

Pillars and robotic arms for industrial robots

AutoLoader

Conveyor Machine

Automatic handling device

Tire Building Machine

spot welding machine

-

Products Details

-

Products Parameters

-

Wie hoch ist die durchschnittliche Vorlaufzeit?

Angebot anfordern

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.