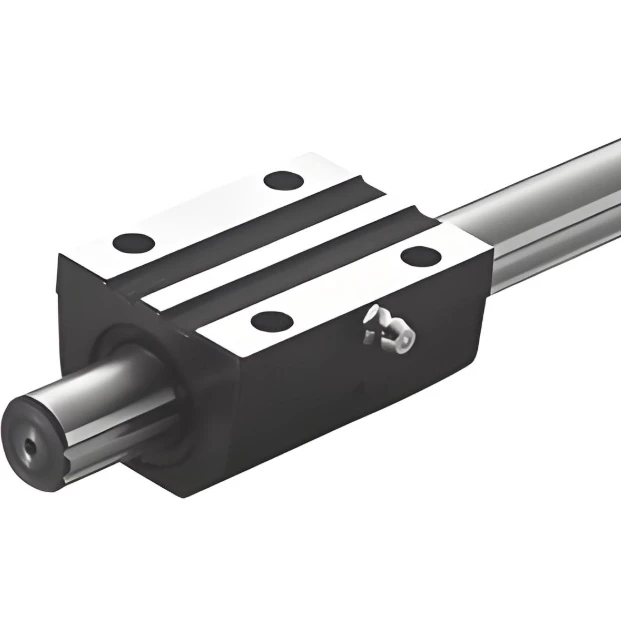

A ball spline is a mechanical linear motion component that enables both rotational and linear movement while maintaining high torque transmission. It consists of a grooved shaft (spline shaft) and a matching ball spline nut that contains recirculating ball bearings. These bearings roll along the grooves of the shaft, reducing friction and ensuring smooth, precise motion in both directions.

Ball splines are ideal for ball spline applications where torque must be transmitted during linear motion—such as in robotics, automatic assembly machines, pick - and - place systems, and precision medical equipment. Unlike standard splines or linear guides, a ball spline combines load - bearing linear motion with the ability to transmit high torque, even under high - speed or oscillating conditions.

Due to the rolling contact of the balls, ball splines offer low wear, long life, and minimal backlash. The compact design allows for space - saving installation, and the high load capacity ensures reliable performance under dynamic operating conditions. Ball splines can also be configured with features such as ball spline bearing, rotary encoders, or anti - rotation mechanisms for complex motion systems.

Ball splines are available in a variety of sizes, preload levels, and materials including carbon steel and stainless steel. They are typically precision - ground for high accuracy and may be treated with surface coatings for corrosion resistance or improved durability.