-

Products Features

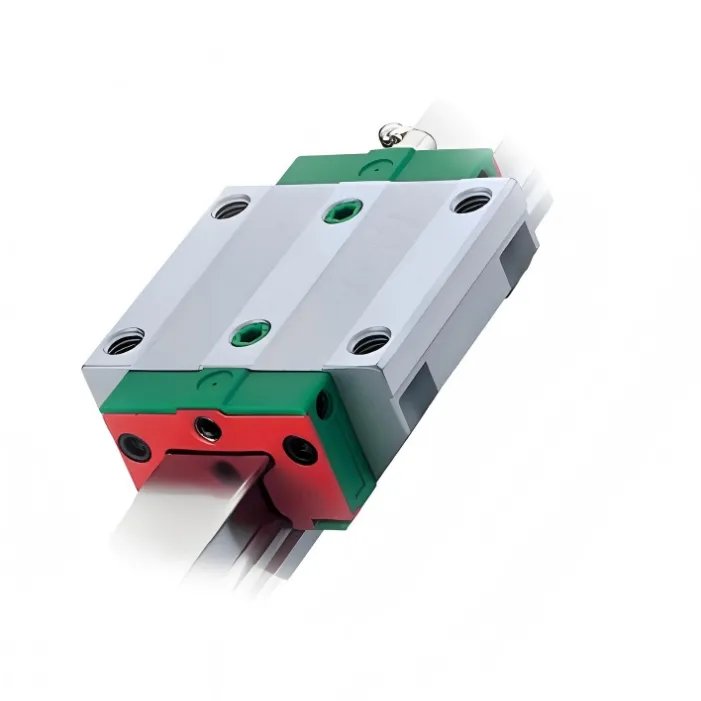

High torque resistant design

Adopting an O-shaped four column circular arc tooth contact structure, a long arm anti torque mechanism is formed through DB combination, significantly improving the anti torsion ability and being able to withstand composite loads in the left, right, and up and down directions simultaneously. Compared to traditional DF configurations, the anti torque arm is longer (A1>A), making it suitable for high torque application scenarios.

Optimize lubrication and dust prevention system

New oil circuit design: ensuring sufficient lubrication inside the slider, reducing wear and extending lifespan

Stainless steel dust cover tape: quick installation design to prevent dust from entering the slider through bolt holes and prevent damage to the sealing part of the oil scraper

High rigidity and high load capacity

Four directional load characteristics, supporting heavy load (C-type) and overweight load (H-type) specifications, adapting to different strength requirements

-

Products Application

Woodworking machinery: resistant to irregular torque in wood processing

Precision Grinding Machine/Grinding Machine: Ensuring High Precision Feed Stability

Automated handling equipment: suitable for high-speed and heavy-duty scenarios

Injection molding machine/welding equipment: capable of withstanding impact loads and vibrations

-

Product Detail

-

-

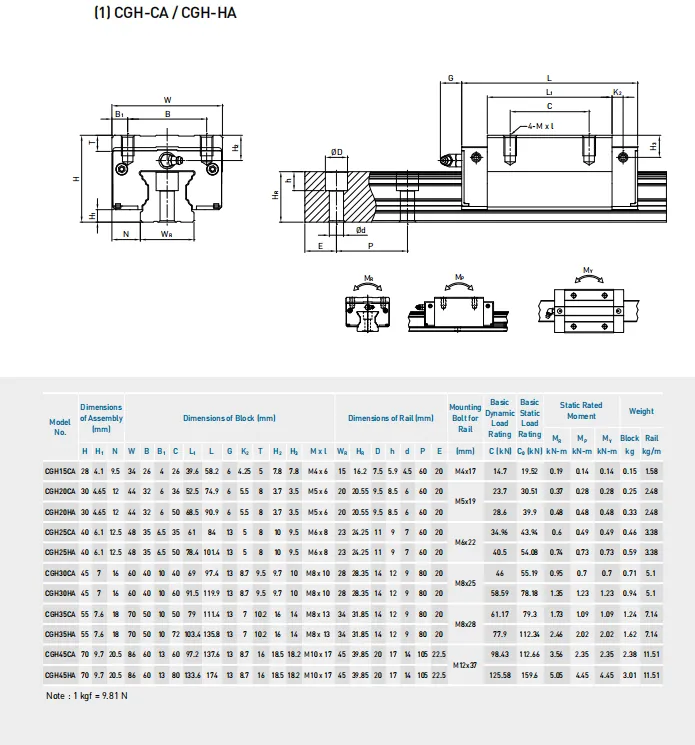

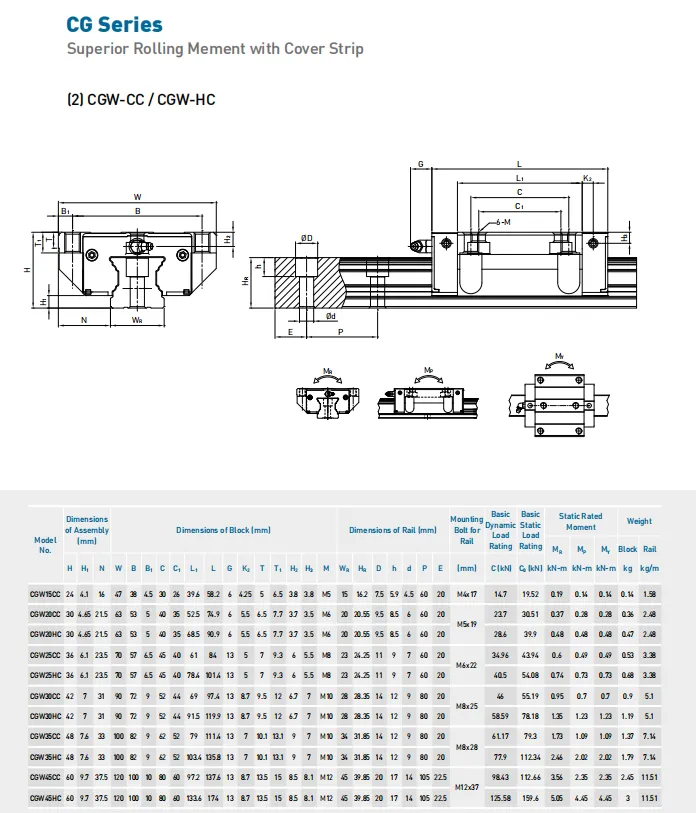

Parametri del prodotto

-

Qual è il tempo medio di consegna?

Richiedi un preventivo

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.